Welded butterfly valve adopts a precise J-shaped elastic sealing ring and a three-eccentric multi-layer metal hard sealing structure. It is widely used in industrial pipelines with a medium temperature of 425 in metallurgy, electric power, petrochemical, water supply and drainage, municipal construction, etc., to adjust the flow and take away the fluid. The welded butterfly valve is divided into cast steel welded butterfly valve, stainless steel welded butterfly valve and chrome-molybdenum steel welded butterfly valve. The welded butterfly valve is a three-eccentric structure. The valve seat and valve plate sealing surface are made of stainless steel with different hardness, which has good corrosion resistance and long service life. The valve can have a two-way seal.

Feature

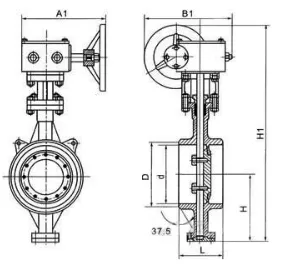

1. It is designed and manufactured with a new structural form of welding the centerline disc plate and the short structural steel plate. It has a compact structure, light weight, easy installation, small flow resistance, large circulation volume, avoids the influence of high temperature expansion, and is easy to operate.

2. There are no connecting rods, bolts, etc. It works reliably and has a long service life. It can be installed in multiple stations and is not affected by the flow direction of the medium.

|

Nominal diameter |

DN(mm) |

50~700 |

||||

|

Nominal pressure |

PN(MPa) |

0.6 |

1.0 |

1.6 |

2.5 |

4.0 |

|

Test pressure Ps(MPa) |

Strength test |

0.9 |

1.5 |

2.4 |

3.75 |

6.0 |

|

Sealing test |

0.66 |

1.1 |

1.76 |

2.75 |

4.4 |

|

|

Airtightness test |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

|

|

Applicable media |

Water, steam, oil, acid corrosion, etc. |

|||||

|

Applicable temperature |

Carbon steel: -29℃~425℃ Stainless steel: -40℃~600℃ |

|||||