Valves are crucial components in every industrial system—from oil & gas pipelines to chemical plants and power generation. A single failure can lead to costly downtime or safety hazards. That’s why non destructive testing for valves (NDT) is an essential step in manufacturing and maintenance.

This guide explains what non destructive testing for valves means, the methods used, international standards, and how to build a cost-effective inspection plan.

What Is Non Destructive Testing for Valves?

Non destructive testing for valves involves inspecting and evaluating valve components without damaging them. It identifies hidden flaws like cracks, porosity, and inclusions that cannot be detected by the naked eye.

The goal is simple: ensure valve integrity while keeping parts reusable. NDT has been a trusted quality control practice since the 1930s and is now required by major industry standards such as ASME B16.34, API 6D, and MSS SP-55.

Why NDT Is Critical for Valve Reliability

· Early defect detection: Finds cracks, voids, or inclusions before failures occur.

· Cost-efficient: Eliminates waste by testing parts without destroying them.

· Compliance: Meets safety codes in oil, gas, and power applications.

· Re-certification: Supports valve re-rating for higher pressure or temperature service.

· Material verification: Confirms correct alloys and heat treatment conditions.

Without non destructive testing for valves, hidden flaws can compromise performance and lead to severe operational risks.

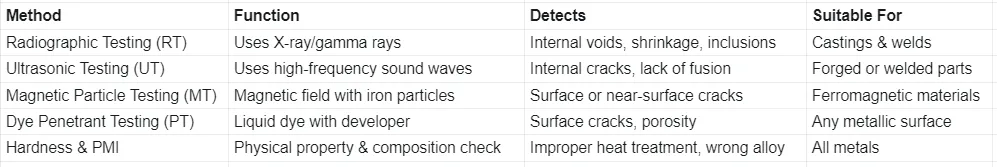

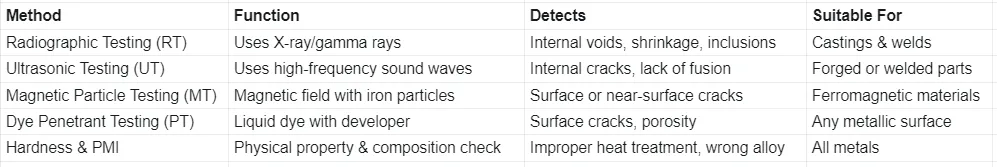

Main Methods of Non Destructive Testing for Valves

By combining surface and volumetric techniques, engineers achieve a complete integrity profile of each valve component.

International Standards and Best Practices

To guarantee accuracy and acceptance, non destructive testing for valves should comply with recognized standards:

· ASME B16.34: Defines NDT requirements for valve components and critical zones.

· API 6D / 6A: Specifies valve inspection procedures for oil and gas applications.

· MSS SP-55 & SP-93: Provide reference acceptance levels for visual and NDT inspection.

· ISO 9712 / SNT-TC-1A: Ensure inspectors are certified and competent.

Following these standards improves traceability, safety, and customer confidence.

How to Implement an Effective Valve NDT Program

1. Identify critical areas – Focus on valve body, bonnet, and weld zones.

2. Select proper NDT methods – Use RT and UT for internal flaws, MT or PT for surface cracks.

3. Prepare surfaces – Clean thoroughly for accurate results.

4. Perform inspection – Apply the method per standard procedure.

5. Interpret results and record data – Document defect type, location, and severity.

6. Repair or re-test if necessary – Recheck repaired areas to confirm compliance.

An organized inspection plan ensures that non destructive testing for valves is consistent and reliable across all production stages.

Benefits of Non Destructive Testing for Valves

✅ Improves valve safety and performance

✅ Extends service life and reduces maintenance costs

✅ Ensures compliance with global industry codes

✅ Builds trust with clients and certification bodies

✅ Enables continuous quality improvement

Whether during manufacturing or periodic maintenance, non destructive testing for valves ensures every component meets the highest quality standards.

Conclusion

In industrial environments where safety, precision, and reliability are non-negotiable, non destructive testing for valves plays a vital role. By combining advanced NDT techniques, certified inspectors, and adherence to global standards such as ASME B16.34 and API 6D, manufacturers and operators can ensure long-term valve integrity and performance.

If you are looking for high-quality industrial valves that have undergone certified non destructive testing, our team is ready to help.

Contact us anytime to learn more about our tested valve solutions and how we can support your projects with proven reliability and compliance.

English

English