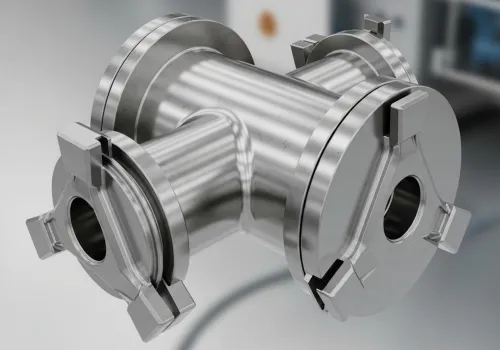

You worry about backflow contaminating your sensitive process lines and ruining expensive batches. Finding a reliable valve that meets strict hygiene standards is a constant headache for many procurement managers. A sanitary check valve is a specialized component that allows fluid to flow in only one direction. It prevents reverse flow in food, beverage, and pharmaceutical lines. Choosing between ball and spring types depends on your specific pressure needs and maintenance capabilities.

I know how hard it is to find the right parts for a complex project. I have seen many projects delay because of wrong choices or poor quality. Let me explain the details to you so you can make a safe decision for your company.

Contamination ruins batches and costs your company a lot of money. Standard valves trap bacteria in crevices, risking your entire production line's safety and compliance with international standards. These valves feature smooth, polished surfaces that prevent bacteria buildup. They allow for Clean-in-Place (CIP) operations, ensuring the system stays sterile without disassembly. Industries like biotech and food processing rely on them to maintain product purity and system integrity.

At Eflow Valve we have supplied pipeline products since 1996, and I have learned that the simple function of a valve is vital. A sanitary check valve does not use electricity or air. It works automatically. This is very important for your safety systems. When you look at the valve from the outside, you cannot see if it is open or closed. This means the internal quality must be perfect. These valves are different from the heavy industrial valves we supply for oil and gas, but the principle is the same: safety and control. In sanitary industries like food, beverage, and pharma, the valve must self-drain. It helps evacuate process lines and vent air. If the valve fails, the fluid flows back. This causes cross-contamination. I remember a project we supported in Europe. The client ignored the surface finish of the valve. Bacteria grew inside the rough metal. They had to shut down for a week. You must choose valves that meet 3-A or ASME-BPE standards. Our products go through strict inspections by SGS or TUV. We ensure that the "wet" parts (the parts touching your liquid) are smooth and clean. This prevents the "sticking" issues that happen with poor-quality shutters or discs.

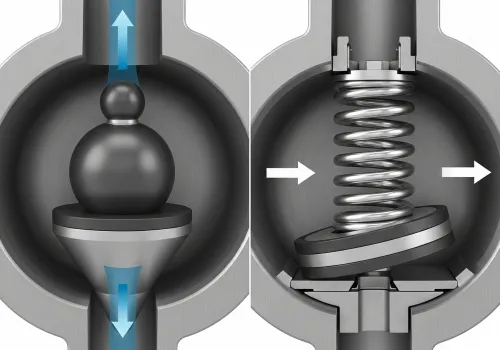

Choosing the wrong mechanism causes leaks or frequent maintenance issues for your team. You do not want to replace valves every month because the design does not fit the fluid type. Ball check valves use a floating sphere to block reverse flow, making them great for heavy fluids. Spring check valves use a spring-loaded disc for a tighter seal. Your choice depends on viscosity, installation space, and required cracking pressure.

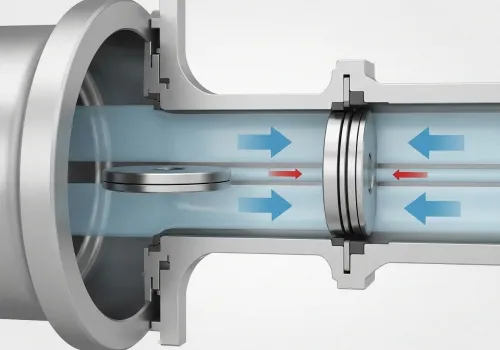

We need to look at this closely. In my experience working with EPC companies, engineers often fight about which type is better. As a purchasing manager, you need to know the facts to save costs. Ball Check Valves These use a simple ball inside a Y-shaped body. When the liquid flows, the ball moves out of the way. When the flow stops, gravity or back pressure pushes the ball into a seat.

· Bad points: They are not 100% leak-proof. Sometimes, a little liquid escapes. Spring Check Valves These use a spring to push a disc against the seat. The liquid must push hard enough to compress the spring. This is called "cracking pressure."

· Good points: They seal very tight. They are small and fit in tight spaces. They work well in vertical or horizontal pipes.

· Bad points: The spring can wear out. They do not stop "water hammer" (big pressure spikes), but they help reduce it. Here is a simple table to help you compare:

| Feature | Ball Check Valve | Spring Check Valve |

|---|---|---|

| Mechanism | Floating Ball | Spring-loaded Disc |

| Sealing | Good (minor leakage possible) | Excellent (Positive shutoff) |

| Maintenance | Low (Self-cleaning) | Low (Replace spring/O-ring) |

| Space Needed | Larger (Y-body shape) | Compact |

| Best Use | Heavy fluids, particulate flow | Clean liquids, tight spaces |

Buying from unreliable suppliers leads to mismatched specs, poor material certificates, and delayed projects. You need a partner who understands heavy thickness and high precision without constant supervision. You must look at the maximum operating pressure and the specific material standards like 3-A or ASME-BPE. A good supplier provides full certification and testing reports. This guarantees the valve handles the stress of your specific EPC project environment.

When you source a sanitary check valve, you are not just buying metal. You are buying trust. I have worked with many purchasing managers in Germany and across Europe. I know you care about the "One-Stop" solution. You do not want to buy pipes from one guy and valves from another. At Eflow Valve, we integrate everything. When you select a valve, you must check the "Cracking Pressure." This is the pressure needed to open the valve. If you get this wrong, the valve stays closed, and your pump burns out. Also, think about the connection type. Do you need a Tri-Clamp for easy cleaning? Or a welded end for a permanent fix? We supply both. We follow ISO 9001 and ISO 14001 standards. This means every valve we ship to you has a paper trail. I once helped a client who needed valves for a high-purity water system. They bought cheap valves first. The springs rusted because the steel grade was wrong. We replaced them with high-grade stainless steel LKC-2 style valves. We solved the problem immediately. This is why we say we are "Customer-Oriented." We look at your whole project, not just the price tag.

To choose the right sanitary check valve, you must look at the flow direction, pressure needs, and fluid type. Ball valves are good for heavy flow, while spring valves give a tight seal. Eflow Valve is your reliable partner for these high-quality pipeline products.