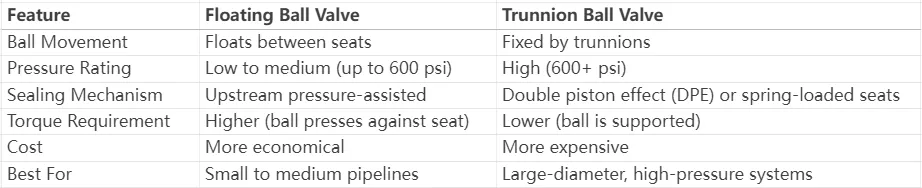

When selecting the right ball valve for your industrial application, understanding the difference between floating ball valve vs trunnion ball valve is crucial. Both types serve the same basic function—controlling fluid flow—but their designs, performance, and ideal use cases vary significantly.

This guide will compare floating vs trunnion ball valve designs, explaining their key differences, advantages, disadvantages, and best applications to help you make an informed decision.

A floating ball valve has a ball that is not rigidly fixed to the stem. Instead, it "floats" slightly between two sealing seats. When the valve closes, upstream pressure pushes the ball against the downstream seat, creating a tight seal.

✔ Simple design – Fewer moving parts

✔ Cost-effective – Generally cheaper than trunnion valves

✔ Good for low-to-medium pressure – Best under 600 psi (depends on size & material)

✔ Bubble-tight seal – Effective for shutoff applications

· Water treatment

· HVAC systems

· Low-pressure oil & gas pipelines

· Chemical processing (non-corrosive fluids)

A trunnion ball valve has a ball anchored by a trunnion (a shaft or pivot) at the top and bottom. This design reduces operating torque and handles higher pressures more efficiently.

✔ Fixed ball design – Supported by trunnions for stability

✔ High-pressure & large-bore capability – Works well in 600+ psi systems

✔ Lower operating torque – Easier to actuate in high-pressure applications

✔ Double piston effect (DPE) seats – Enhanced sealing under extreme conditions

· High-pressure oil & gas pipelines

· LNG (liquefied natural gas) processing

· Large-diameter pipelines (12" and above)

· Cryogenic applications

The choice between a floating ball valve vs trunnion ball valve depends on your system requirements:

✅ Choose a Floating Ball Valve If:

· You need a cost-effective solution

· Your system operates at low-to-medium pressure

· The valve size is small to medium (typically under 12")

· A simple, reliable shutoff is sufficient

✅ Choose a Trunnion Ball Valve If:

· You deal with high-pressure (600+ psi) or large-diameter pipelines

· Lower operating torque is needed (for automation)

· The application involves cryogenic or severe service conditions

· Long-term durability is critical

The difference between floating ball valve and trunnion valve ultimately comes down to pressure, size, and application requirements.

· Floating ball valves are ideal for cost-sensitive, low-to-medium pressure systems.

· Trunnion ball valves excel in high-pressure, large-scale, or critical service applications.

Still unsure which valve suits your needs? Contact our experts today for personalized recommendations!