Gas backflow causes expensive damage to compressors and halts your entire production line. You face safety risks and costly downtime if your pipeline equipment fails. A reliable check valve is the only solution to keep your operation running smoothly. A gas line check valve is a safety device that ensures gas flows in only one direction. It automatically closes to prevent backflow when the flow reverses. This protects critical equipment like compressors and pumps. It is essential for maintaining pressure and safety in oil, gas, and construction pipelines.

You now know the basic definition. However, selecting the wrong valve for your specific piping system can lead to disaster. I will explain the specific types and criteria you need to look for.

There are many valve designs, but using the wrong one creates vibration and flow issues. You need to know which design fits your specific pipeline layout. The type of valve you choose depends on space, pressure, and the specific gas application. Some valves are built for high-speed discharge, while others are designed to fit into tight spaces between flanges.

In my experience at Eflow Valve, I see many project managers struggle with valve selection. You must match the valve type to the function. Here is a breakdown of the most common types we supply to EPC companies.

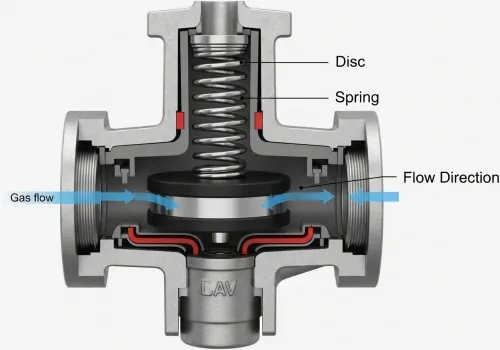

1. Axial Flow Check Valves These are critical for compressor discharge. In this design, gas moves parallel to the center axis. The valve uses a spring-loaded disc. When pressure drops, the spring pushes the disc back against a seal. This is very fast. It prevents "slamming" and reduces water hammer. If you are dealing with reciprocating compressors, this is often the best choice.

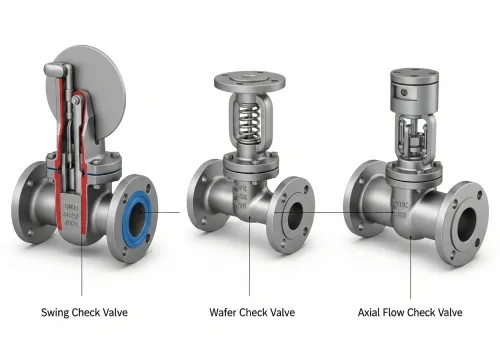

2. Swing Check Valves This is a traditional design. A disc swings on a hinge or trunnion. It opens with forward flow and closes with gravity or reverse flow. These are simple and cost-effective. However, they are not ideal for flow with frequent reversals or pulsation.

3. Wafer Check Valves These are designed to save space. They fit between two flanges. They are lightweight and cheaper than full-body valves. If your construction project has limited space in the piping design, a wafer style is a smart choice.

4. Nozzle-Style Check Valves These are a specific type of axial valve. They are excellent for low-pressure systems or intermittent flow. They use a diffuser to smooth out the flow. This reduces pressure loss. When we integrate products for our clients, we look at the whole system. We ensure the gas line check valve matches the steel pipe specifications perfectly.

Ignoring specific gas characteristics leads to corrosion and valve failure. You must analyze the operating environment before you sign the purchase order. Your valve must handle the specific pressure, temperature, and chemical composition of the gas. If you miss one factor, the valve will leak or seize up.

I have worked with purchasing managers in Germany and worldwide for years. The most successful projects pay attention to the details. You cannot just pick a standard valve from a catalog. You must consider these factors. Gas Composition and Characteristics You need to know the fluid viscosity and specific gravity. Is the gas corrosive? Does it contain particulate matter? If the gas is "sour" (contains H2S), you need special materials. We often supply NACE-compliant materials for these harsh environments. Pressure and Cracking Pressure Cracking pressure is the minimum pressure required to open the valve.

· Too High: The valve restricts flow. This causes energy loss.

· Too Low: The valve might not close fast enough. You must balance this carefully. The valve rating (like ANSI 150, 300, 600) must match your pipeline pressure limits. Material Selection The body and trim materials determine the lifespan of the valve. Here is a simple guide we use at Eflow Valve:

| Material | Application Suitability | Cost |

|---|---|---|

| Carbon Steel (WCB) | General non-corrosive gas and oil lines. Standard for most construction. | Low |

| Stainless Steel (SS304/316) | Corrosive environments, high moisture, or offshore applications. | Medium |

| Alloy Steel (F11/F22) | High-temperature applications. Good for thermal power plants. | High |

| Duplex Steel | Extremely corrosive environments, like seawater or sour gas. | Very High |

Regulatory Compliance

For your projects, especially in Europe or for major EPC contracts, certificates are non-negotiable. Ensure your supplier provides API (American Petroleum Institute) or ISO certifications. We ensure our gas line check valve products meet API 6D or API 594 standards.

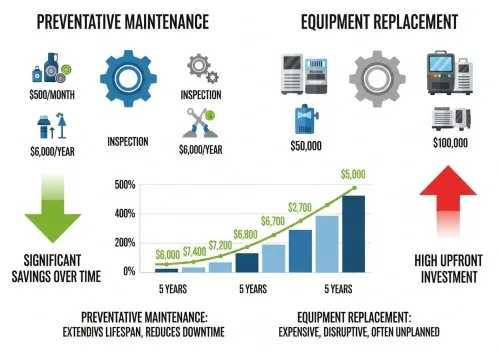

Buying a cheap valve often results in expensive repairs later. You need to view the valve as an investment in the longevity of your entire piping system. A high-quality check valve prevents "chatter" and "water hammer," which destroy pipes. It also requires less maintenance, saving you labor costs over time.

As a purchasing manager, you want to save costs. But saving on the initial purchase price is often a mistake. You should look at the Total Cost of Ownership (TCO). A good gas line check valve adds value in several ways.

1. Preventing Compressor Damage Compressors are the most expensive part of a gas pipeline. If gas flows backward when a compressor stops, it spins the compressor in reverse. This can destroy the bearings and the motor. A fast-acting check valve stops this instantly. It acts as an insurance policy for your expensive machinery.

2. Minimizing Chatter Chatter happens when a valve opens and closes rapidly. This is caused by turbulence or low flow. It creates noise and wears out the valve seat.

· The Solution: Proper sizing. Do not just match the valve size to the pipe size. Sometimes, the valve needs to be smaller than the pipe to ensure it stays fully open. At Eflow Valve, we help you calculate the correct flow coefficient (Cv) to avoid this.

3. Reducing Downtime Every time you stop production to replace a valve, you lose money. Axial flow valves have no external moving parts. They are sealed and robust. They last longer. This means your team spends less time on maintenance and more time on production.

4. Versatile Installation Modern check valves work in vertical or horizontal positions. This gives your design engineers more freedom. It simplifies the construction process at the site.

5. One-Stop Integration This is where my company helps. You do not want to buy pipes from one place and valves from another. We integrate the supply. We ensure the flanges on the pipe match the flanges on the valve perfectly. This avoids installation errors and delays at the construction site.

To secure your gas pipeline, you must choose the right check valve type, material, and size. This prevents backflow damage and saves operational costs. Trust a professional integration supplier like Eflow Valve for reliable results.