Leaking valves ruin projects and damage hard-earned reputations. You might think installation is simple, but ignoring flow orientation causes expensive failures. I will show you exactly when direction matters. The short answer is: it depends on the design. Standard floating ball valves are usually bidirectional. However, trunnion-mounted, vented, or single-seated valves are unidirectional. You must check the valve body for an arrow marking to answer "do ball valves have a flow direction" correctly for your specific project requirements.

Two ball valves side by side, one with a clearly cast flow arrow on the body and one without, highlighting the visual difference I have seen many engineers ignore this small detail. It leads to big problems during pressure testing. Let us look at the specific types so you never make this mistake.

Choosing the wrong type stops production lines and wastes budget. You need to know the mechanical differences to buy the right equipment for your piping system. Bidirectional valves seal from both sides, making them versatile for general lines. Unidirectional valves seal only on one side to handle higher pressures or specific media. Understanding this distinction answers do ball valves have a flow direction for your specific engineering needs.

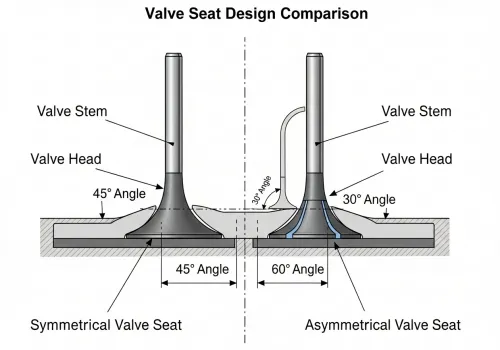

Cross-section diagram comparison of a symmetrical valve seat versus an asymmetrical seat design We need to look inside the valve to understand why this happens. I often explain to my clients that the difference lies in the seat design. A bidirectional valve, which is very common in standard water and low-pressure gas lines, uses a symmetrical design. The upstream and downstream seats are identical. The ball floats between them. Pressure pushes the ball against the downstream seat to create a seal. The flow can come from either side without issues. Unidirectional valves are different. Engineers design them for specific, often harsher, conditions. These valves usually have an asymmetrical seat design or a cavity relief feature. If you use a trunnion-mounted ball valve, the ball is fixed. The seat rings move against the ball. In this case, the upstream pressure activates the seat. If you reverse the flow, the pressure might push the seat away from the ball. This causes a leak. Another critical factor is the "vented ball." Some valves have a small hole drilled into the ball. This hole prevents pressure buildup inside the valve body cavity when the valve is closed. This feature is vital for volatile liquids like chlorine or liquid ammonia. If you install this valve backward, the hole faces the wrong way. The valve will leak continuously when closed.

| Feature | Bidirectional Valve | Unidirectional Valve |

|---|---|---|

| Flow Path | Two-way (Reversible) | One-way (Fixed) |

| Seat Design | Symmetrical | Asymmetrical / Self-relieving |

| Pressure Handling | Standard / Low to Medium | High Pressure / Severe Service |

| Common Type | Floating Ball | Trunnion Mounted / Vented |

| Installation Risk | Low (Can't install backwards) | High (Must follow arrow) |

You are on a busy construction site and time is money. You need to know the installation orientation immediately without hunting for a lost manual. Look for a cast arrow on the valve body first; this is the standard indicator. If there is no arrow, the valve is likely bidirectional. Knowing these visual cues resolves the question do ball valves have a flow direction during urgent site inspections.

Close up photo of a steel valve body showing a cast arrow indicating flow direction Identifying the flow direction is usually straightforward, but it requires attention. The most reliable method is the arrow. Manufacturers cast or engrave an arrow on the body of unidirectional valves. This arrow points from the inlet to the outlet. You must install the valve so the media travels in the direction of the arrow. I have seen people get confused by the handle. Do not rely on the handle orientation to determine flow direction. The handle shows if the valve is open or closed. Parallel means open. Perpendicular means closed. It tells you nothing about which way the water or oil should flow. If you cannot find an arrow, you might need to look at the "Tag" or nameplate. The nameplate usually carries the technical symbols. An arrow symbol on the tag confirms the direction. If there is no arrow on the body and no arrow on the tag, it is safe to assume the valve is bidirectional. Sometimes, you might deal with a vented ball valve for cryogenics. You can spot this by looking into the port (if the valve is not installed). You will see a small hole on the upstream side of the ball. That hole must face the high-pressure side when the valve is closed

Step 1: Clean the valve body and look for a cast arrow.

Step 2: Check the metal nameplate for flow symbols.

Step 3: Consult the technical drawing or "General Arrangement" (GA) drawing.

Step 4: Inspect the ball for a vent hole (pressure relief hole). We always ensure our Eflow Valve products have clear markings. Ambiguity on a job site leads to errors. Clear marking prevents those errors.

A simple installation error turns a high-quality valve into a liability. The consequences range from minor leaks to dangerous ruptures in your piping system. Installing a unidirectional valve in reverse prevents the seat from sealing against pressure. This causes internal leakage, rapid seat wear, and potential body failure. Ensuring proper orientation is the only way to guarantee safety and system integrity.

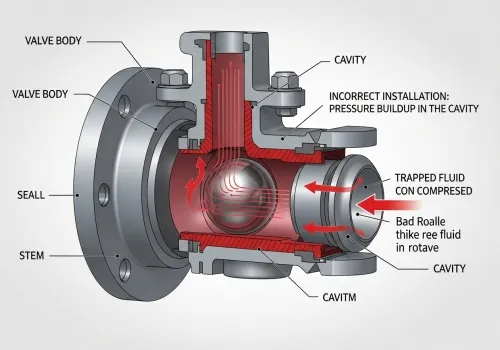

Diagram showing pressure buildup in a valve cavity due to incorrect installation The consequences of ignoring flow direction are severe. I want to break down exactly what happens inside the valve so you understand the risk. First, you face Internal Leakage. In a unidirectional valve, the seal relies on pressure coming from the correct side. If pressure comes from the wrong side, it pushes the seat away from the ball. The valve might look closed, but the medium flows past the seat. In a gas line, this is dangerous. In a water line, it ruins your isolation capability. Second, you risk Cavity Pressure Lock. This is the most dangerous scenario. Liquid trapped inside the valve body cavity can expand if the temperature rises (thermal expansion). Unidirectional valves often have "self-relieving" seats. These seats move slightly to release this excess pressure back into the line. If you install the valve backward, the relief mechanism is on the wrong side. The pressure has nowhere to go. It builds up inside the body. This can deform the ball, damage the stem, or even burst the valve body. Third, you get Accelerated Wear. The flow hits the sealing surface at the wrong angle. This causes "wire drawing" or erosion of the soft seat material (like PTFE). You will replace the valve much sooner than expected.

| Consequence | Description | Severity |

|---|---|---|

| Leakage | Media passes the closed valve. | Medium |

| Seat Damage | Erosion of the sealing material. | Medium |

| Body Rupture | Thermal expansion explodes the body. | Critical |

| Process Contamination | Backflow enters clean zones. | High |

I advise all my clients to paint a flow arrow on the pipe itself next to the valve location. This gives the installer a double check before they bolt the flanges.

Standard floating valves work both ways, but high-performance valves often have a specific direction. Always check for the arrow on the body to ensure safe and leak-free operation.