Choosing the wrong valve for your pipeline project can lead to dangerous leaks and expensive system shutdowns. Do not let a simple misunderstanding of valve design compromise your engineering safety. The main difference between floating ball valve and trunnion valve lies in how the ball is anchored. In a floating valve, line pressure pushes the ball against the downstream seat to seal.

In a trunnion valve, the ball is fixed by a shaft, and spring-loaded seats move against the ball to create the seal. I remember a project meeting with a purchasing manager from Germany a few years ago. He needed to cut costs on a large pipeline project. He almost swapped all the high-pressure valves to floating types to save money. I had to explain that while he might save money now, the maintenance costs later would be huge. This guide will help you understand these differences so you can make the right choice for your company.

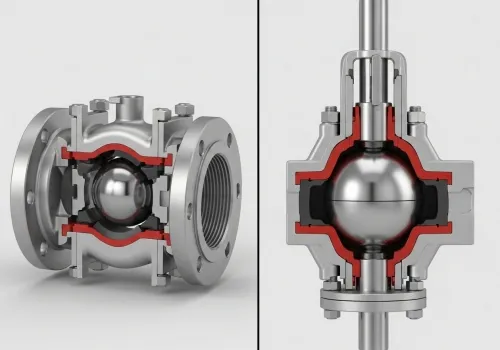

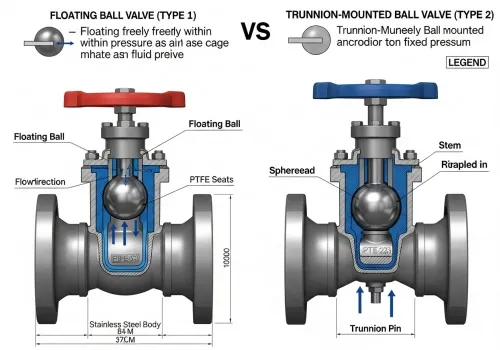

It is hard to see what happens inside a valve once it is installed in the pipe. If you do not understand the internal design, you cannot predict how it will handle pressure. The floating ball valve features a ball that is suspended by the valve seats and is free to move slightly. The trunnion ball valve anchors the ball at the top and bottom, keeping it stationary while the seats move toward it.

Let me take you onto our factory floor at Eflow Valve. When we manufacture a floating ball valve, we do not fix the ball to the stem rigidly. The stem has a slot, and the ball fits into it. This allows the ball to "float" or move slightly downstream when the medium flows through. The pressure from the gas or liquid pushes the entire ball against the rear seat. This pressure is actually what creates the seal. It is a simple and effective design that we have used since 1996. On the other hand, the trunnion ball valve is more complex. In this design, we add a second shaft at the bottom of the ball, called a trunnion. This holds the ball firmly in one place. The ball can rotate, but it cannot move sideways. Because the ball cannot move, the pressure cannot push it against the seat to make a seal. Instead, we install spring-loaded seats. These springs push the seats against the ball. This is a major difference between floating ball valve and trunnion valve design. Here is a simple breakdown of the components:

| Feature | Floating Ball Valve | Trunnion Ball Valve |

|---|---|---|

| Ball Support | Supported only by the two valve seats | Supported by a top stem and a bottom trunnion shaft |

| Sealing Method | Pressure pushes the ball into the seat | Springs push the seats into the ball |

| Movement | Ball moves slightly downstream | Ball rotates only; no side movement |

| Complexity | Simple design, fewer parts | Complex design, more parts (springs, bearings) |

| Stem Connection | Loose connection to allow float | Rigid connection |

High pressure can ruin a valve if the design is not strong enough to handle the force. Using a valve that is too weak for the system is a safety risk that no purchasing manager wants to take. You should strictly use trunnion valves for high-pressure and large-diameter applications, typically above 6 inches or Class 600. Floating valves are the best choice for smaller, low-to-medium pressure lines where budget is a priority.

| Parameter | Floating Ball Valve Application | Trunnion Ball Valve Application |

|---|---|---|

| Size Range | Best for small sizes (1/2" to 6") | Essential for large sizes (up to 60" or more) |

| Pressure Class | Usually up to Class 150 or 300 | Handles Class 600, 900, 1500, and 2500 |

| Torque | High torque required at high pressure | Lower operating torque |

| Low Pressure Sealing | Can be poor (needs pressure to seal) | Excellent (springs create the seal) |

| Typical Industry | Water, light gas, general plumbing | Oil & Gas transmission, High-pressure steam |

Budgets are always tight, and you do not want to spend money on features you do not need. However, buying the cheaper option now can lead to frequent replacements and expensive downtime later. Floating ball valves are significantly cheaper and easier to maintain for standard uses. However, the higher investment in trunnion valves is necessary for critical systems to ensure long-term reliability and safety.

As a supplier committed to sharing China-made quality with the world, I am honest about costs. The difference between floating ball valve and trunnion valve prices is real. Trunnion valves have more parts. They have trunnions, bearings, springs, and more complex body castings. This makes them more expensive to make and more expensive to buy. For a standard water line or a low-pressure gas line in a building, I would never recommend a trunnion valve. It is a waste of your budget. The floating valve is perfect there. It is compact, light, and cheap. But for a major oil pipeline or a refinery project, the "cheap" floating valve is dangerous if used in the wrong spot. The seat wear on a floating valve is uneven because all the pressure is on one side (the downstream side). This means you have to replace the seats more often. Trunnion valves distribute the wear evenly. Also, think about operation costs. If you need an electric actuator, a floating valve needs a big, powerful motor to overcome the friction. A trunnion valve can use a smaller motor. Sometimes, the money you save on the smaller actuator makes the total price of the trunnion package very competitive.

| Aspect | Floating Ball Valve | Trunnion Ball Valve |

|---|---|---|

| Initial Cost | Low | High |

| Maintenance Frequency | Medium (Seats wear faster) | Low (Even wear distribution) |

| Repair Difficulty | Easy (fewer parts) | Harder (more internal components) |

| Actuation Cost | Higher (Needs larger actuators) | Lower (Needs smaller actuators) |

| Long-term Value | Good for non-critical lines | Best for critical, high-load lines |

The difference between floating ball valve and trunnion valve comes down to pressure and support. Use floating valves for standard, low-pressure needs. Use trunnion valves for high-pressure, critical safety lines.