Choosing the right valve for your piping project is often stressful. You worry about leaks, pressure loss, or buying the wrong equipment for the job. I want to solve this confusion for you today. So, what is a globe valve? It is a type of linear motion valve used to stop, start, and regulate fluid flow. The name comes from its spherical body shape. It is excellent for throttling flow, meaning it can partially open to control the amount of fluid passing through, unlike a gate valve which is only for on or off tasks.

I have spent many years in the steel pipe and valve industry. I see many purchasing managers struggle with the difference between valve types. They see a list of specs and feel overwhelmed. I want to break this down simply. We will look at how these valves work. We will look at materials. We will look at why you might choose them. This guide will help you make the best decision for your company.

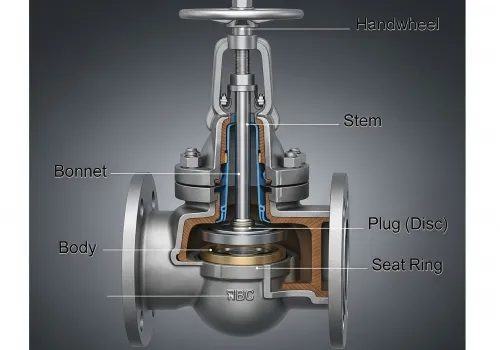

You need to know how the inside of the valve works. This helps you understand where to put it in your system. The design is unique. The fluid must change direction to pass through the valve. This structure is what allows for good control, but it also creates resistance.

When we talk about what is a globe valve, we must talk about the flow path. In a standard globe valve, the water or gas does not move in a straight line. It flows up, turns, passes the seat, and turns again. This is often called a "Z-body" design. I remember a project with a client from a large oil refinery. He needed to reduce the pressure of steam in a specific line. A ball valve was too fast. A gate valve would break under the vibration. I showed him the inside of a globe valve. I explained that the "baffle" or partition inside forces the fluid to slow down. This shape is perfect for throttling. However, you must be careful. Because the fluid hits a wall and turns, the pressure drops. If your system needs to keep pressure very high, this might be a problem. You need to calculate this pressure drop. There are three main body designs you should know:

| Body Type | Flow Characteristic | Best Application |

|---|---|---|

| Z-Body (Standard) | High pressure drop. Fluid turns 90 degrees twice. | General water and steam lines where pressure loss is okay. |

| Y-Body | Lower pressure drop. The stem is at a 45-degree angle. | High-pressure lines where you want less resistance. |

| Angle Body | Fluid enters bottom, exits side (90-degree turn). | Used when the pipe itself turns a corner. Saves an elbow fitting. |

You now know how it works. But where do you put it? This is the most common question I get from EPC managers. Globe valves are versatile. But they are not for every pipe. They are heavy and can be costly. You need to use them where control is the main goal.

I have supplied piping equipment since 1996. I have seen globe valves in many sectors. They are very common in cooling water systems. They are also common in fuel oil systems. The most critical use is in bypass systems. Let’s say you have a main control valve. It is expensive and complex. You need to fix it. You open the bypass line. You use a globe valve there. You can adjust the flow manually to match the system needs while the main valve is offline. Here are the key industries where we see high demand:

1. Cooling Water Systems: You need to regulate flow based on heat.

2. Fuel Oil Systems: The flow rate determines the burn rate.

3. Chemical Feed Systems: Precision is key here.

4. Boiler Vents and Drains: You need a tight seal to prevent leaks. I once worked with a German purchasing manager. He was building a power plant extension. He wanted to save money by using gate valves everywhere. I warned him. I told him that if he uses a gate valve to throttle flow, the vibration will destroy the disk. It is called "wire drawing." The high-speed fluid cuts the metal. He listened to me. We switched the regulation lines to globe valves. It saved his company thousands of Euros in maintenance later. You should also think about the fluid type. What is a globe valve good for? Clean liquids and gases. It is not good for thick slurries. The internal baffle traps dirt. If you have thick, muddy fluid, it will get stuck. The valve will not close. For those lines, use a full-bore ball valve instead.

The shape is important. But the metal is what keeps it safe. The material must match the pressure and heat. Globe valves are usually cast. The shape is too complex to forge easily. However, for very small or very high-pressure valves, we use forged steel.

We take quality seriously. At Eflow Valve, we focus on ISO and CE standards. For a globe valve, the body material is the first step.

· Cast Iron: Cheap. Good for low pressure and water.

· Carbon Steel (WCB): The standard for oil and gas. It handles high heat.

· Stainless Steel: Essential for corrosive chemicals or food.

· Alloy Steel: For extreme heat in power plants (above 350°C). But the most important part is the "Trim." The trim includes the stem, the seat, and the disk. These parts rub against each other. They need to be hard. We often use Bronze for water valves. For steam, we use Stainless Steel. There is a process called "Hard Facing." We put a layer of Stellite (a cobalt alloy) on the seat. This makes it very hard. It stops the metal from scratching. I always check the trim chart when I get an order. I recall a large order for a coastal project in Southeast Asia. The air was salty. The fluid was seawater. Standard carbon steel would rust in months. We proposed a specialized Duplex Stainless Steel for the valve bodies. The cost was higher upfront. But the lifespan was ten times longer. The client trusted our "one-stop" advice. We supplied the pipes, the flanges, and these special valves together. When we manufacture these, we test the seat. We grind the surface until it is perfectly flat. This ensures full contact. We also check the "Galling." This is when metal sticks to metal. By choosing different hardness levels for the disk and the seat, we prevent this. Here is a quick reference for Trim selection:

| Service Condition | Recommended Trim Material |

|---|---|

| General Water/Oil | Bronze or 13% Chrome Steel |

| High Pressure Steam | Stellite (Hard Faced) |

| Corrosive Acid | 316 Stainless Steel or Monel |

| Low Temp (Cryogenic) | 304 Stainless Steel |

We ensure every valve passes third-party inspection. SGS or TUV comes to our factory. They check the pressure. They check the dimensions. This is how we maintain our AAA credit rating.

To summarize, what is a globe valve? It is your best choice for regulating flow. It offers precise control and a tight shut-off. While it creates some pressure drop, its ability to throttle fluid is unmatched. Whether you need carbon steel for oil or stainless for chemicals, choosing the right material is vital. At Eflow Valve, we use our decades of experience to help you find the perfect match for your project.