Air leaks destroy efficiency. You lose money and time when pressure drops unexpectedly in your pipeline projects. I will explain how one small part prevents this major headache. A check valve for air compressor is a mechanical device that ensures air flows in only one direction. It allows compressed air to move from the pump to the tank, but it physically blocks air from flowing back into the pump when the unit shuts down.

I know that small components often cause the biggest problems in large engineering projects. If you understand this valve, you can save your company significant maintenance costs.

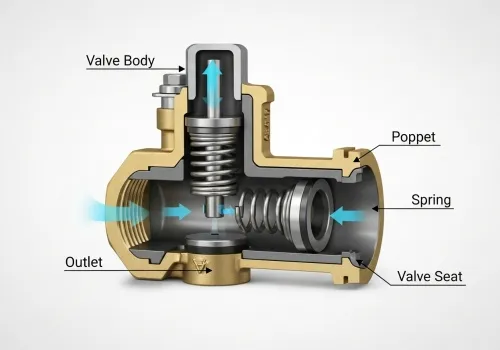

I want to start with the basics of the internal design. It is simple but brilliant. If you pick up a check valve for air compressor, you can blow air through one side easily. If you turn it around and blow, the air stops completely. This is the core function. Inside the valve body, there is usually a disc or a ball. A spring pushes this disc against a seal, which we call the seat. When the air pressure from the compressor pump hits the disc, it pushes the spring back. This opens a path for the air. The air flows into the tank or the pipeline. However, when the compressor stops, the airflow stops. Now, the pressure in the tank tries to rush back out. This back pressure pushes against the disc from the other side. The spring also pushes the disc closed. These two forces work together to create a tight seal. The higher the pressure in the tank, the harder the disc pushes into the seat. This prevents any air from escaping back into the pump. It creates a "trapped" zone of pressure. I have created a table below to help you identify the main parts of this system:

| Component Name | Primary Function | Common Material |

|---|---|---|

| Valve Body | Holds all internal parts and connects to pipes | Brass, Stainless Steel, or Cast Iron |

| Disc / Ball | The moving part that opens or closes flow | Stainless Steel or Polymer |

| Seat | The surface where the disc seals | PTFE (Teflon) or Metal |

| Spring | Pushes the disc closed when flow stops | Stainless Steel |

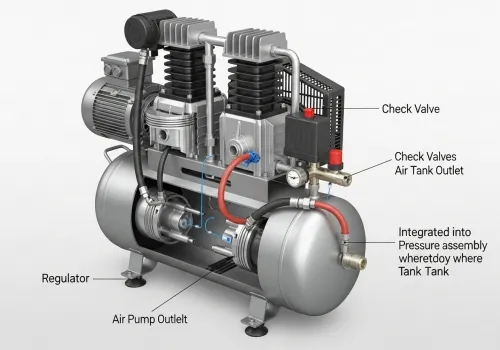

I see different setups depending on the project scale. In my 18 years in the industry, I have seen that piston compressors and screw compressors use these valves differently. You need to know where to look when you are sourcing parts for a construction site. On a reciprocating piston compressor, you will usually find three main check valves. There are two inside the piston head. One lets air in (inlet), and one lets air out (outlet). If these fail, the compressor simply pushes air back and forth without building pressure. But the most critical one is between the compressor pump and the air receiver tank. When the pump stops, the pipe between the pump and the tank must release its pressure. We call this "blow-down." If the tank check valve fails, the entire tank will lose air back through the pump. On rotary screw compressors, the system is slightly more complex. There is an inlet check valve. This prevents oil and air from "vomiting" out of the intake filter when the machine stops. I have seen messy workshops where this valve failed, and oil covered the floor. There is also a minimum pressure check valve at the outlet. It ensures the internal system has enough pressure to lubricate the screws before it sends air to your plant. Here is a breakdown of the specific locations and their risks:

1. Piston Head Inlet: If this fails, air pushes back out the filter.

2. Tank Entry: If this fails, the motor has to start against high pressure, which can burn out the motor.

3. Screw Element Outlet: Prevents backflow that can rotate the screws in reverse, which destroys the air end.

I often see purchasing managers buy the cheapest valves, but this is a mistake. The material quality matters immensely. At Eflow Valve, we focus on durability. A check valve for air compressor faces high heat, vibration, and moisture. If you choose a cheap plastic or low-grade brass valve for a heavy industrial site, it will fail. For harsh environments, such as coastal construction or chemical plants, I always recommend Stainless Steel (SS304 or SS316). It resists corrosion from the water condensate that forms in compressed air. If the valve corrodes, the "seat" becomes rough. The disc cannot seal properly, and you get leaks. How do you know if your valve is broken? There is a common trick. If your compressor shuts off, and you hear a constant hissing sound from the pressure switch, do not replace the switch. The switch is just the messenger. The leak is actually coming from the tank check valve. The air is leaking back from the tank, up the line, and out of the unloader valve on the switch. You also need to consider the connection type. Is it threaded (NPT/BSP) or flanged? In large pipeline projects, we prefer flanged connections for easier maintenance. You can unbolt the valve without cutting the pipe. Use this checklist before you approve a purchase order:

· Pressure Rating: Does the valve handle the maximum system pressure (e.g., 20 bar)?

· Temperature: Can the seal material (like Viton or PTFE) handle the discharge heat (often over 100°C)?

· Flow Rate: Is the valve large enough? A small valve restricts flow and wastes energy.

· Material: Is the body made of verified steel or high-grade brass?

The check valve protects your equipment from backflow and maintains system pressure efficiently. You must select the right material and size to ensure safety and avoid costly motor failures.