Struggling to identify the right valve components for your pipeline project? Ignoring specific design details often leads to system failures and wasted budget. I will explain exactly what makes these valves tick. The essential parts of a butterfly valve include the body, disc, seat, and stem. These components work together in a quarter-turn motion to stop or start fluid flow. Knowing how each part functions helps you choose the most durable equipment for your industrial application.

I know that understanding these components can be tricky, so let me break it down simply for you.

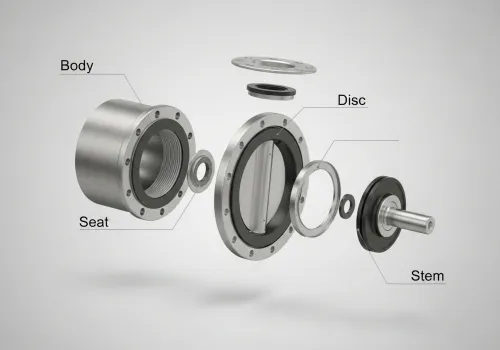

Do you know exactly which components handle the pressure in your piping system? If you choose the wrong materials for these specific parts, you risk leaks and expensive downtime. The critical parts of a butterfly valve consist of the stationary body, the moving disc, the sealing seat, and the stem. These four main elements determine the pressure rating, chemical resistance, and overall lifespan of the valve in your project.

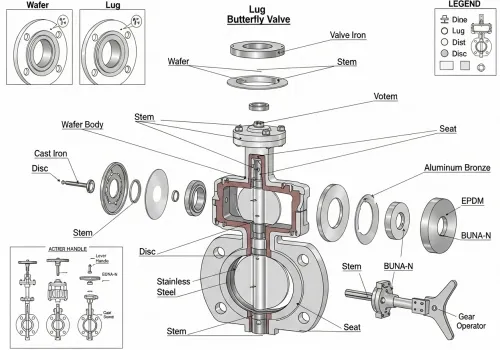

In my experience at Eflow Valve, I have seen that knowing the specific function of each part helps in making the right purchase. Let's look closer at these components. First, the Valve Body is the outer shell. It fits between the pipe flanges. The most common designs I see are the Wafer type, which is sandwiched between flanges, and the Lug type, which has threaded holes for bolts. The body must be made of strong material like Ductile Iron or Stainless Steel to withstand the pressure of the fluid. Second, the Disc is the heart of the valve. It acts like a gate. When the valve is closed, the disc blocks the line. When open, it turns 90 degrees to let fluid pass. Manufacturers often design the disc to be thin to improve flow. Third, the Seat is the inner lining. It creates a leak-proof seal when the disc pushes against it. This is usually made of elastomers like EPDM or rigid PTFE, but for high-temperature jobs, we use metal seats. Fourth, the Stem connects the disc to the handle or actuator outside. It transmits the turning force. Here is a simple table to help you compare the materials often used for these parts:

| Part | Common Material | Main Function |

|---|---|---|

| Body | Ductile Iron, Carbon Steel | Holds the valve in the pipeline and contains pressure. |

| Disc | Stainless Steel, Bronze | Stops or allows flow; acts as the barrier. |

| Seat | EPDM, NBR, PTFE, Metal | Ensures a tight seal so the valve does not leak. |

| Stem | Stainless Steel | Connects the internal disc to the external operator. |

Understanding these parts of a butterfly valve allows you to specify the right requirements for your supplier, ensuring the product fits your needs perfectly.

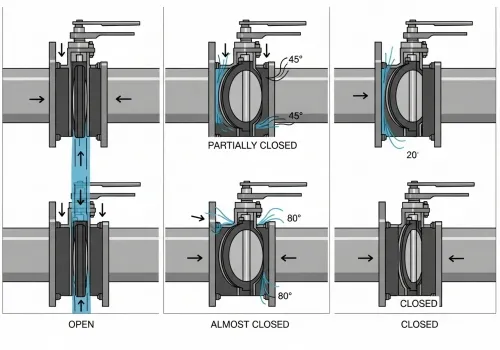

You might have the right parts, but do you understand how they move together? A lack of knowledge about the operation mechanism can lead to improper usage and rapid wear and tear. The working principle depends on the stem rotating the disc against the seat. A simple 90-degree turn moves the valve from fully open to fully closed, providing quick and efficient flow control for your system.

When I explain this to my clients, I describe it as a quarter-turn action. This is different from a gate valve that requires many turns. The operation starts at the Actuation Mechanism. This can be a simple hand lever for small pipes, a gear wheel for larger pipes, or an electric or pneumatic actuator for automated systems. When you apply force to the actuator, it turns the Stem. Since the Stem is connected to the Disc, the disc rotates. In the open position, the disc stays parallel to the flow. This allows the water or oil to pass around it. However, the disc is always in the center of the flow, which causes a slight pressure drop. When you close the valve, the stem turns the disc perpendicular to the flow. The edges of the disc press firmly into the Seat. This is where the quality of the seat matters. If the seat is soft (resilient), the disc squeezes into it to stop all leaks. I also want to mention the Double Offset design. In standard valves, the stem goes through the center of the disc. In double offset types, the stem is slightly off-center. This cam-like action pulls the disc away from the seat immediately when it opens. This reduces friction and wear on the seal. This is very important if you are buying valves for high-frequency use. Here is how the actuation methods compare:

· Manual Lever: Good for small sizes, fast operation.

· Gearbox: Necessary for large sizes (above DN 200) to reduce the effort needed to turn the wheel.

· Pneumatic/Hydraulic: Uses air or fluid pressure for automatic, remote control.

· Electric: Uses a motor for precise control and positioning.

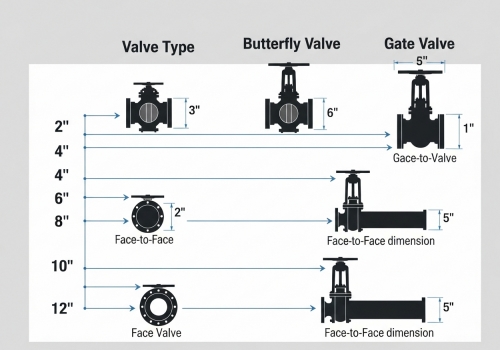

Are you worried that your current piping design is too heavy or too expensive? Traditional valves can be bulky and costly, taking up valuable space and increasing your shipping and installation budget. Butterfly valves offer a massive advantage because they are lightweight, compact, and cost-effective. Their simple design requires less material than gate or globe valves, making them the smarter choice for large-diameter pipelines in water and energy sectors.

I always tell my partners in the EPC industry that choosing the right valve type saves money in two ways: purchasing cost and installation cost. First, look at the Design. Because the parts of a butterfly valve are compact, the face-to-face dimension is short. A gate valve of the same size might be three times wider and much heavier. This means you do not need as many pipe supports. It also makes them easier to install in tight spaces, like on a ship or in a crowded plant. Second, consider the Cost. For small pipes, the price difference is small. But once you go above DN 300 (12 inches), a butterfly valve is much cheaper than a gate or ball valve. This is because it uses less metal. Since Eflow Valve supplies large projects, we know that these savings add up quickly. Third, they are Versatile. You can use them for water supply, wastewater, fire protection, and fuel handling. They handle large volumes of fluid very well. While they are mainly for on/off service, they can do some flow regulation, though I suggest avoiding this for long periods to protect the disc. Finally, let’s look at Maintenance. There are fewer moving parts. There are no pockets to trap debris like in a gate valve. The seals are often replaceable. This keeps your long-term operating costs low. Here is a summary of the benefits:

1. Lightweight: Easier to handle and install.

2. Compact: Saves space in your facility.

3. Fast Acting: Opens and closes in seconds.

4. Low Maintenance: Simple design means fewer things can break.

5. High Performance: Options like double-eccentric designs handle high pressures efficiently.

To select the best equipment, you must understand the body, disc, seat, and stem. These parts of a butterfly valve define its performance, ensuring your project runs smoothly and efficiently.