Pipeline failures cost industrial projects millions in downtime every year. You need the correct flow control strategy to prevent catastrophic backflow and ensure efficient shutoff. Choosing the wrong valve type destroys system integrity. A ball valve allows precise on/off control via a manual or automated rotational mechanism, while a check valve automatically prevents backflow using media pressure. Understanding the distinct functions of the ball valve and check valve ensures system safety and operational efficiency.

I have seen many purchasing managers struggle with the specific nuances of valve selection. You might think a valve is just a valve, but the engineering reality is different. I want to share my experience regarding these two critical components. You will learn exactly how to choose between them to save your company budget.

Confusion regarding valve operation causes accidents on the construction site. You cannot afford a valve opening when it is supposed to close. The actuation method defines the safety of your personnel. The ball valve uses a quarter-turn handle or actuator to mechanically stop fluid flow. The check valve relies entirely on pressure differentials to open and close automatically without human intervention.

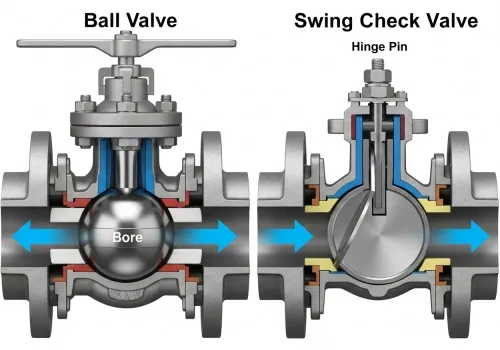

I always explain the difference to my clients using a simple analogy. A ball valve is like a door you must walk over and lock yourself. A check valve is like a turnstile that only spins one way. The ball valve is an active device. You or an automated system must tell it what to do. Inside the housing, a spherical closure unit with a hole (the port) rotates 90 degrees. When the hole aligns with the pipe, flow continues. When it rotates perpendicular to the pipe, flow stops. This provides a tight seal. I recommend these for isolation applications where you need a bubble-tight shutoff. The check valve is a passive device. It works based on the mood of the pipeline. If the pump pushes fluid forward, the valve opens. If the pump stops and gravity pulls the fluid back, the valve slams shut. We call this "backflow prevention." At Eflow Valve, we test these mechanisms rigorously. The correct combination of ball valve and check valve in a system protects pumps from reversing and spinning backwards. Here is a breakdown of the mechanical differences:

| Feature | Ball Valve | Check Valve |

|---|---|---|

| Actuation | Manual or Actuated (Electric/Pneumatic) | Automatic (Media Flow Driven) |

| Primary Function | Isolation (On/Off control) | Backflow Prevention |

| Flow Resistance | Low (especially in Full Port models) | Moderate (Spring or disc creates drag) |

| Bidirectional | Yes (Flow goes both ways) | No (One-way flow only) |

| Leakage Class | Tight Sealing (Class VI often) | Allowable leakage in some standards |

Wrong placement of valves leads to unmanageable leaks and equipment failure. Your system integrity depends entirely on the strategic location of each component. Operational efficiency drops significantly with bad design choices. Install ball valves upstream of equipment to allow for isolation during maintenance. Place check valves immediately downstream of pumps to protect the expensive machinery from reverse flow damage or water hammer.

I have worked with EPC companies for over 18 years. I frequently see designs where the engineer forgets the check valve near the compressor. This is dangerous. You must use ball valves in the following scenarios:

1. Stop/Start Control: You need to stop flow to a section of the plant.

2. Emergency Shutoff: You need a quick 90-degree turn to kill the line.

3. Flow Regulation (Limited): You can use V-port ball valves for throttling, though globe valves are better. You must use check valves in these scenarios:

4. Pump Protection: This is non-negotiable. Fluid flowing back into a pump spins the impeller in reverse. This breaks the shaft.

5. Vertical Lines: Gravity pulls fluid down. A check valve stops the column of water from draining the system.

6. Mixing Lines: You prevent one media from contaminating the source of another. Mixing the two types causes problems. A "ball check valve" exists, but do not confuse it with a standard ball valve. A ball check valve uses a floating ball to block backflow. It has no handle. I often advise clients on the specific pairing of ball valve and check valve for high-pressure lines. For example, in an oil refinery, you place a Swing Check Valve after the crude pump. You then place a Trunnion Mounted Ball Valve downstream of that check valve. If the check valve fails, you can close the ball valve to repair it. This redundancy is vital.

Corrosion eats your project profits faster than any other factor. Replacing valves requires expensive shutdowns and labor costs. Material selection prevents premature failure and ensures safety. Select valve materials based on fluid chemical properties and system pressure ratings. Stainless steel works best for corrosive media, while carbon steel suits high-heat oil and gas applications. My production team at Eflow Valve focuses heavily on the material quality. A cheap valve is expensive in the long run. When you select a ball valve, you choose between "Floating" and "Trunnion."

· Floating Ball: The pressure pushes the ball against the seat. This is good for low to medium pressure.

· Trunnion Ball: The ball is anchored at the top and bottom. This is essential for large diameters and high pressure. It reduces the torque needed to turn the handle. When you select a check valve, the design matters for the "slam" effect.

· Swing Check: Simple, cheap, but can slam shut loudly (Water Hammer).

· **Tilting Disc:**Closes faster and quieter.

· Piston/Lift Check: Good for high-pressure gas. I recall a project in the Middle East. The client used a standard brass check valve in a sour gas line. The hydrogen sulfide destroyed the internals in weeks. We replaced it with a NACE-compliant stainless steel unit. You must also consider the "Cv value" or flow coefficient. Ball valves typically have a high Cv. They offer little resistance to flow. Check valves have a lower Cv because the fluid must push the disc open. This creates a pressure drop. Your pump must be strong enough to overcome this. Below is a guide for material selection based on my experience:

| Application | Recommended Body Material | Recommended Seat Material |

|---|---|---|

| Potable Water | Ductile Iron / Brass | EPDM |

| Oil & Gas | Carbon Steel (WCB/A105) | PEEK / Nylon / Viton |

| Corrosive Chemical | Stainless Steel (SS316/SS304) | PTFE (Teflon) |

| High Temperature Steam | Chrome Moly Steel | Stellite (Metal Seat) |

Balancing the cost and performance of the ball valve and check valve requires deep industry knowledge. We help our partners make these choices every day.

Ball valves provide manual control and tight shutoff, while check valves offer automatic backflow protection. Eflow Valve integrates both to ensure your pipeline operates safely and efficiently. Choose the right tool.