If you're wondering "how does a butterfly valve work?", you're in the right place. A butterfly valve, also known as a flap valve, is a regulating valve with a circular disc or "butterfly" as its closing mechanism. Understanding its components and operation is essential for proper selection and maintenance.

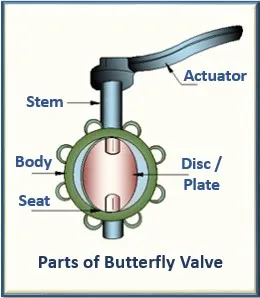

Before diving into how does a butterfly valve work, let's examine its key components:

1. Valve Body - The cylindrical housing that connects to the pipeline and contains all internal parts.

2. Disc (Butterfly) - The rotating element that controls flow by pivoting perpendicular or parallel to the media flow.

3. Stem - The shaft that connects the disc to the actuator and transmits rotational force.

4. Seat - The sealing surface that ensures tight closure (available in soft-seat or metal-seat designs).

5. Actuator - The mechanism (manual lever, gear, pneumatic, or electric) that operates the valve.

6. Bushings/Bearings - Support the stem and reduce friction during operation.

7. Seals/Gaskets - Prevent leakage between components.

The key to understanding how does a butterfly valve work lies in its simple yet efficient design. The disc rotates around its axis within the cylindrical valve body, moving between 0° and 90°. At 90°, the valve is fully open, allowing maximum flow. When closed (0°), the disc blocks the passage completely.

Butterfly valves are lightweight, compact, and consist of only a few components. Their 90° rotation allows for quick opening and closing, making them ideal for applications requiring fast flow control. When fully open, the disc's thickness is the only obstruction, resulting in minimal pressure drop and excellent flow regulation.

There are two main sealing types in butterfly valves:

· Elastic Seals: The sealing ring can be embedded in the valve body or attached around the disc. These seals provide tight shut-off but have temperature limitations.

· Metal Seals: These offer longer service life and can withstand higher temperatures but may not achieve complete sealing.

If the butterfly valve is used for flow control, selecting the correct size and type is crucial.

Thanks to their efficient design, butterfly valves are widely used in:

· Oil, gas, and chemical industries

· Water treatment plants

· Cooling water systems in thermal power plants

The two most common types are wafer-type butterfly valves (mounted between pipe flanges) and flanged butterfly valves (bolted directly to the pipeline flanges).

Now that you know how does a butterfly valve work and its key components, you can appreciate its simplicity, efficiency, and versatility in industrial applications. Whether for flow regulation or isolation, butterfly valves remain a top choice for engineers worldwide.

If you're searching for a qualified valve manufacturer in China, Eflow is your ideal solution. We specialize in a wide range of industrial valves, including ball valves, butterfly valves, check valves, and gate valves. Contact us today to get a quote for your project!