Gate valves are essential components in piping systems, designed to control the flow of liquids and gases by lifting a gate out of the path of the fluid. Among gate valves, the wedge gate valve is a specialized type that offers distinct advantages in certain applications.

This article explores the differences between a wedge gate valve vs gate valve, their working principles, advantages, disadvantages, and ideal use cases to help you select the right valve for your system.

A gate valve is a linear-motion valve that uses a flat or wedge-shaped gate to start or stop fluid flow. When fully open, gate valves provide minimal flow resistance, making them ideal for on/off applications rather than flow regulation.

· Design: Flat or parallel gate

· Operation: Rising or non-rising stem

· Sealing Mechanism: Metal-to-metal or soft-seated

· Applications: Water supply, oil & gas, HVAC systems

Pros:

✔ Full bore design for minimal pressure drop

✔ Suitable for high-pressure and high-temperature applications

✔ Bi-directional flow capability

Cons:

✖ Prone to seat and gate wear over time

✖ Not ideal for throttling (can cause vibration and damage)

A wedge gate valve is a type of gate valve where the gate is wedge-shaped (either solid, flexible, or split) to ensure a tighter seal. The angled design helps the gate wedge firmly into the seats, improving sealing performance under high pressure.

· Design: Wedge-shaped gate (solid, flexible, or split)

· Sealing Mechanism: Enhanced wedging action for better shutoff

· Applications: Steam systems, high-pressure pipelines, power plants

Pros:

✔ Superior sealing under high pressure

✔ Reduced risk of seat leakage

✔ Better performance in high-temperature environments

Cons:

✖ More complex design than standard gate valves

✖ Higher manufacturing cost

· Low to medium-pressure systems

· Water treatment plants

· General industrial applications where tight shutoff isn’t critical

· High-pressure steam lines

· Oil & gas pipelines

· Power generation plants

· Systems requiring zero leakage

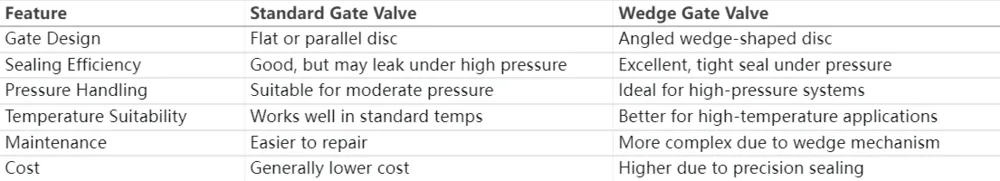

The choice between a wedge gate valve vs gate valve depends on:

· Pressure requirements (wedge valves handle higher pressures better)

· Sealing needs (wedge valves provide tighter shutoff)

· Budget constraints (standard gate valves are more economical)

· Fluid type (wedge valves excel in steam and gas applications)

For most general applications, a standard gate valve suffices. However, for high-pressure, high-temperature, or critical sealing applications, a wedge gate valve is the superior choice.

Understanding the differences between wedge gate valves and standard gate valves helps in selecting the right valve for optimal performance. While standard gate valves are cost-effective for general use, wedge gate valves provide enhanced sealing and durability in demanding environments.

For industries dealing with steam, oil & gas, or high-pressure fluids, investing in a wedge gate valve ensures long-term reliability and leak-free operation.