Choosing the right butterfly valve can make or break your piping system. But when it comes to lug vs wafer butterfly valve, how do you decide which one is the best fit?

This ultimate comparison breaks down the key differences, strengths, and ideal applications of lug and wafer butterfly valves—so you can make an informed decision with confidence.

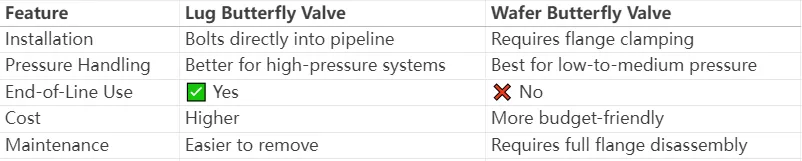

Lug-style butterfly valves feature threaded inserts (lugs) on both sides, allowing them to bolt directly into pipelines without needing full flange support.

✅ Why Choose a Lug Valve?

✔ Easy Maintenance – Remove the valve without dismantling the whole line.

✔ End-of-Line Ready – Perfect for dead-end service and high-pressure systems.

✔ Superior Seal Strength – Handles higher pressures without leaks.

Wafer valves are lightweight, sandwiched between flanges, and rely on flange pressure to stay in place—making them a budget-friendly, space-saving option.

✅ Why Choose a Wafer Valve?

✔ Lower Cost – More affordable than lug valves.

✔ Lightweight Design – Ideal for systems where weight matters.

✔ Space-Saver – Fits snugly in tight pipeline setups.

Go for a Lug Valve If:

· You need high-pressure resistance.

· Your system requires end-of-line service.

· Easy maintenance is a priority.

Choose a Wafer Valve If:

· Cost and weight savings are critical.

· You’re working with limited space.

· The system operates at lower pressures.

Both valves have their strengths—your choice depends on pressure needs, installation requirements, and budget.

Pro Tip: Still unsure? Consult with a valve specialist to match the perfect butterfly valve to your system’s demands!

By understanding the lug vs wafer butterfly valve debate, you can optimize performance, cut costs, and avoid costly mistakes. Make the right choice today!