The chemical processing industry demands high-performance valves capable of handling corrosive fluids, extreme pressures, and stringent safety requirements. Selecting the right valves for the chemical processing industry is critical to prevent leaks, contamination, and operational failures.

This guide explores the top valve types, materials, and selection criteria to optimize safety and efficiency in chemical applications.

When choosing valves for the chemical processing industry, consider these factors:

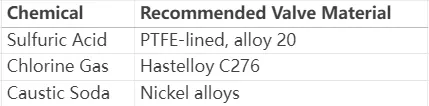

✔ Chemical Resistance – Compatibility with acids, bases, and solvents

✔ Pressure/Temperature Limits – Must exceed process demands

✔ Zero-Leak Seals – Prevent hazardous emissions (API 607/6FA compliant)

✔ Material Durability – Stainless steel, Hastelloy, or PTFE-lined bodies

· Best for: Shutoff control in aggressive media (e.g., HCl, sulfuric acid)

· Materials: 316L SS, alloy C276, PTFE seats

· Industry Use: Petrochemical transfer lines

· Best for: Large-diameter, low-pressure chemical pipelines

· Advantage: Cost-effective solution for slurries and viscous fluids

· Ideal for: Ultra-pure or highly corrosive processes

· Key Feature: Isolates fluid from valve internals

· Applications: Chemical dosing, high-pressure throttling

· Materials: Alloy 20, ceramic-coated

· Critical in: Sulfide stress (NACE MR0175 compliant) environments

For extreme conditions, consider:

· Double Block & Bleed (DBB) Valves – Toxic gas containment

· Bellows Seal Valves – Zero emissions for volatile compounds

· Cryogenic Valves – LNG, liquid nitrogen (-196°C)

With decades of experience supplying valves for the chemical processing industry, we help you:

· Avoid material incompatibility failures

· Select ASME/NACE compliant designs

· Reduce lifecycle costs with low-maintenance valves

Need Industry-Specific Valve Solutions? Contact our chemical processing specialists today!