When selecting valves for critical pipeline systems, fully welded ball valves have become the preferred choice over traditional split-body designs. Their robust construction and superior performance make them ideal for demanding industries like oil & gas, chemical processing, and power generation.

In this article, we explore the five key advantages of fully welded ball valves compared to split-body valves, helping you make an informed decision for your next project.

Unlike split-body valves that rely on bolted connections, fully welded ball valves feature a one-piece welded body construction. This eliminates potential leakage points at flange joints, ensuring zero fugitive emissions—a critical requirement for hazardous fluid applications.

Why it matters:

✔ No gaskets or seals that can degrade over time

✔ Ideal for high-pressure gas pipelines (ASME B16.34 Class 1500+)

✔ Complies with EPA and ISO 15848-1 emission standards

The continuous weld in fully welded ball valves provides:

• 30-50% higher burst pressure resistance vs. split-body designs

• Uniform stress distribution (FEA-verified)

• Eliminates body-seat misalignment risks

Case Study: A North Sea offshore platform reported 60% fewer valve failures after switching to fully welded designs.

Split-body valves require periodic:

✖ Gasket replacements

✖ Bolt re-torquing

✖ Seal inspections

Fully welded ball valves offer:

✓ 100% maintenance-free operation for decades

✓ No disassembly required for seat refurbishment (using advanced injection systems)

The welded construction of fully welded ball valves:

• Prevents crevice corrosion at body joints

• Allows use of corrosion-resistant overlays (Inconel 625, Hastelloy C276)

• Withstands H₂S environments per NACE MR0175

Material Options:

▸ Carbon steel (ASTM A350 LF2)

▸ Stainless steel (ASTM A182 F316)

▸ Duplex stainless (UNS S31803)

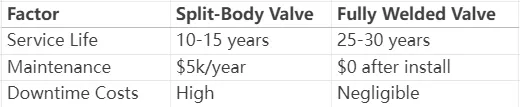

While split-body valves have lower upfront costs, fully welded ball valves deliver greater ROI through:

From leak-proof performance to lifetime cost savings, fully welded ball valves outperform split-body alternatives in virtually every critical metric. For engineers specifying valves for:

• High-pressure gas transmission

• Cryogenic LNG applications

• Corrosive chemical services

The choice is clear—fully welded ball valves provide unmatched reliability where failure isn’t an option.

Ready to upgrade your system? Contact our engineers today for API 6D-certified solutions.