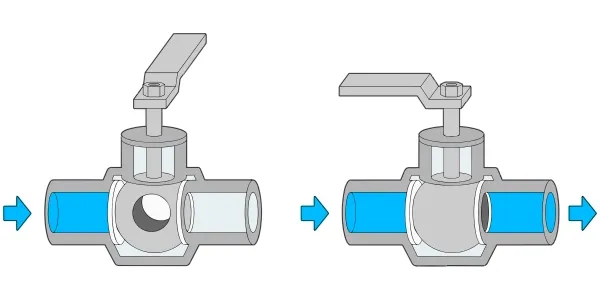

Struggling with a leaking valve? Ball valve shut offs might be your solution. These valves are known for their reliability and efficiency in controlling fluid flow. Ball valves are an effective shut-off mechanism due to their design featuring a rotating ball with a bore. When aligned with the pipeline, flow continues; when perpendicular, it stops instantly, ensuring minimal leakage.

Understanding how ball valves work can enhance your system's performance, but let's dig deeper.

When reliability is a concern, the ball valve shut off provides peace of mind. The design is simple yet effective. Ball valves are reliable shut-off components due to their sturdy construction. A rotating ball with a bore controls flow. When aligned with the pipeline, the fluid passes freely; turned perpendicular, it blocks flow instantly, offering tight sealing.

For those needing detailed insight, explore the components that make ball valves excel:

· Valve Stem: Connects to the actuator.

· O-Rings: Prevents leaks.

· Housing: Supports internal components.

· Ball: Controls flow.

· Seat: Seals the ball. Understanding these parts ensures you choose the right valve for your needs.

Deciding between manual and actuated ball valves? It’s all about application needs. Manual ball valves require physical operation and are suitable for simple systems. Actuated ball valves, powered by electric or pneumatic systems, are better for complex or automated processes, offering greater precision and safety. Here’s a closer look at their differences in a comparison table:

| Type | Advantages | Disadvantages |

|---|---|---|

| Manual | Cost-effective, simple to use | Limited to non-remote areas |

| Electric | Precise, integrates with systems | Depends on power, costly |

| Pneumatic | Rapid response, safe in hazards | Needs air system, adds maintenance needs |

| Your choice depends on system complexity, cost, and safety requirements. |

Connection type can impact your valve's effectiveness. Here's what to consider. Ball valves connect in various ways, including threaded, flanged, and union connections. Threaded options are cost-effective but prone to leaks. Flanged systems suit high-pressure needs, while true union types allow easy maintenance.

| Connection Type | Description | Applications | Advantages |

|---|---|---|---|

| Threaded | Male/female threads, easy install | Residential, small-scale systems | Cost-effective, easy to replace |

| Flanged | Bolt holes, strong attachment | Industrial, high-pressure systems | Easy to install/remove |

| True Union | Easy removal without pipe disturbance | PVC, frequent maintenance | Extends lifespan, easy assembly |

| Consider your operational needs to select the right connection. |

Ball valves ensure reliable shut-offs, making them ideal for diverse applications and systems.