When choosing the right valve for your application, understanding the types of butterfly valves is essential. These versatile valves are critical in managing fluid flow in various systems, from industrial to residential applications.

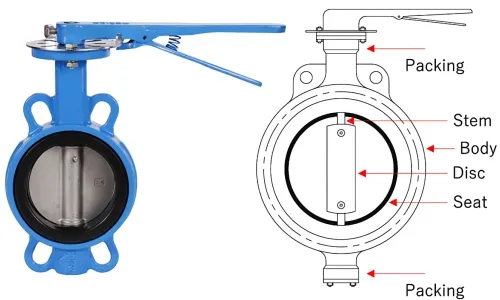

Butterfly valves are classified by material, configuration, mounting type, and actuation method. Let's explore these criteria to help you select the best option for your needs. Butterfly Valve Cross-Section

Carbon Steel: Economical and suitable for general use.

Stainless Steel: Used in demanding environments for its corrosion resistance.

Exotic Materials: Titanium and similar materials are ideal for corrosive or special applications like seawater exposure. Valve Seats are another crucial component, available in:

Rubber-lined: Best for low-temperature, non-abrasive applications.

Plastic-lined: Ideal for chemical and abrasive environments.

Metal: Suited for high-pressure and high-temperature settings.

Configurations dictate how the disc engages the valve seal:

Concentric: Stem centers in the disc and pipe bore, meeting the seat early in the rotation.

Single-offset: Stem is behind the disc, reducing seat contact for longer life.

Double-offset: Features two offsets, minimizing disc-seat contact and suitable for higher pressures.

Triple-offset: Includes an offset stem and cone-shaped disc, minimizing friction. These are typically made of advanced materials and used in demanding applications.

Butterfly valves connect to pipelines through different methods:

Wafer: Simple and secure, but requires a full system shutdown for maintenance.

Lug: Allows easy removal and maintenance, although it handles lower pressure.

Semi-Lug and Double-Flanged: Less common, providing specific benefits in particular scenarios.

Butterfly valves are controlled through:

Manual: Lever turns the valve open or closed with a quarter-turn.

Gearbox: Eases the torque needed but increases operation time.

Pneumatic/Electrical Actuators: Offer significant opening torque for remote or demanding environments. Pneumatic Actuated Butterfly Valve

Butterfly valves are popular in:

Hydro-electric power stations

Pneumatic systems

Process industries like cooling water, slurry transport Their compact design and low-pressure drop make them a preferred choice where space is limited. However, they are not suitable for precise flow throttling.

These valves require minimal maintenance. Geared units often feature intrinsic lubrication. Regular inspections every six months can prevent leakages and ensure functionality.

Aspect

Type

Materials

Carbon Steel, Stainless Steel, Exotic

Seats

Rubber, Plastic, Metal

Configuration

Concentric, Single, Double, Triple

Mounting

Wafer, Lug, Semi-Lug, Double-Flanged

Actuation

Manual, Gearbox, Pneumatic/Electrical

Understanding the types of butterfly valves ensures optimal performance and longevity in your systems. Select the correct options for your specific conditions to take full advantage of their capabilities.