You face tight project deadlines and cannot afford pipeline failures. Choosing the wrong equipment leads to leaks, high costs, and angry clients. What is a butterfly valve? It is a quarter-turn valve used to isolate or regulate flow. A metal disc rotates 90 degrees to block or open the pipe. It is lighter and cheaper than other valves, making it perfect for large industrial water and gas systems.

I have worked with many purchasing managers who struggle to find the right balance between quality and cost. You want a product that lasts but fits the budget. In this article, I will explain the details of this valve type. I will show you why Eflow Valve is the partner you need for your next EPC contract.

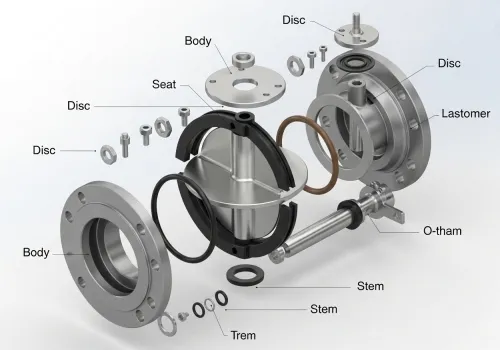

Are you worried about component failure shutting down your entire system? Understanding the internal parts is the first step to ensuring long-term reliability. The construction relies on four main components: the body, the disc, the stem, and the seat. Together, they ensure a tight seal and durability. Knowing these parts helps you specify the right materials for your specific media and pressure requirements to avoid corrosion.

I know that as an experienced manager, you need to know exactly what goes into your pipeline. Let's look deeper at the parts. The valve body fits between pipe flanges. We usually see flanged, double lug, and wafer types. This body holds the other parts. The disc is the most critical part. It acts like a gate. It stops the fluid. At Eflow Valve, we ensure the disc design reduces drag. This improves flow when the valve is open. The stem connects this disc to the handle or actuator outside. It transmits the torque. If the stem is weak, the valve fails. The seat is the lining inside the body. It creates the seal. We use strong elastomers or metal seals. This ensures zero leakage. For high-performance needs, we look at the double eccentric design. This design moves the disc slightly away from the center. It reduces wear on the seat. Here is a quick look at the materials we often use:

| Component | Common Material | Function |

|---|---|---|

| Valve Body | Ductile Iron / Stainless Steel | Holds pressure and connects to flanges. |

| Disc | Stainless Steel / Bronze | Blocks or allows flow. |

| Seat | EPDM / PTFE / Metal | Provides the anti-leak seal. |

| Stem | High-grade Steel | Transfers turning force to the disc. |

We pay attention to these details. We want to ensure that every valve matches your specific project needs.

A valve is useless if you cannot operate it efficiently and safely. Choosing the wrong actuator leads to operational headaches and safety risks for your team. Actuation depends on your system's automation level and torque needs. Options range from simple manual levers and handwheels with gearboxes to complex pneumatic, hydraulic, and electric actuators for remote control. The right choice ensures precise flow management and system safety.

I see many projects where the wrong actuation method slows down operations. You need to choose based on size and location. Manual Operation For smaller valves, a simple lever is enough. It is fast and cheap. But for sizes over DN 200, you cannot use a lever. The torque is too high. You need a gearbox and a handwheel. This makes it easy to turn the valve. If the valve is buried underground, we provide extension spindles. This allows your team to operate it from ground level without a manhole. Automated Operation For big plants, you need automation.

· Pneumatic Actuators: These use compressed air. They open and close very fast. They are often used for safety shut-offs.

· Hydraulic Actuators: These are for the biggest valves. They provide massive force. They are used in high-pressure lines. At Eflow Valve, we configure the mountings to ISO standards. This means you can easily fit any actuator later.

| Actuator Type | Best For | Speed | Cost |

|---|---|---|---|

| Hand Lever | Small sizes, easy access | Fast | Low |

| Gearbox | Large sizes, manual use | Slow | Medium |

| Electric | Remote control, precision | Medium | High |

| Pneumatic | Quick shut-off, safety | Very Fast | Medium/High |

High project costs and tight spaces create constant pressure on your budget. Traditional valves often take up too much room and cost too much money. Butterfly valves offer a compact, lightweight design that significantly reduces installation costs and space requirements. They provide quick 90-degree operation and are versatile enough for water, slurry, and gas applications. This makes them superior to gate valves for large-diameter pipes.

I often get asked, "What is a butterfly valve's main advantage over a gate valve?" The answer is usually weight and space. Lightweight and Compact A butterfly valve is narrow. The distance between faces is short. This means you use fewer materials. The valve weighs less. You do not need heavy pipe supports. This saves money on steel work. It also makes installation easier for your crew. Low Maintenance The design is simple. There are few moving parts. If you choose a double-eccentric design from Eflow Valve, the wear is even lower. The seal does not rub against the seat until the very last moment of closing. This extends the life of the valve. Cost-Effective For large diameters (above DN 300), the cost difference is huge. A gate valve of this size is very heavy and expensive. A butterfly valve provides the same shut-off capability for a fraction of the price. Fast Acting You only need a quarter-turn to close it. A gate valve requires many turns of a wheel. In an emergency, speed matters. Comparison: Butterfly Valve vs. Gate Valve

| Feature | Butterfly Valve | Gate Valve |

|---|---|---|

| Weight | Light | Heavy |

| Space Needed | Minimal | Large |

| Operation Speed | Fast (90° turn) | Slow (Multi-turn) |

| Cost (Large Size) | Low | High |

| Flow Control | Good for throttling | On/Off only |

I recommend these valves for water distribution, power plants, and chemical processing. They solve the problem of space and budget without losing performance.

Butterfly valves are the smart choice for efficient, cost-effective flow control in large pipelines. Eflow Valve provides the quality and expertise you need for your success.