Pipelines carry essential resources like oil, gas, and water every single second. Without a control mechanism, these powerful flows become dangerous and chaotic. You need reliable mechanical switches to regulate pressure and stop leaks instantly. Valves act as the mechanical control gates in any piping system. To answer exactly how do valves work, they physically obstruct the pipe's internal passage using a closure element—like a ball, disc, or gate. This regulates fluid movement, stopping flow completely or throttling it to manage pressure and volume effectively.

Many people think pipes are just static metal tubes that sit there. The reality is that the valves make the system alive and functional.

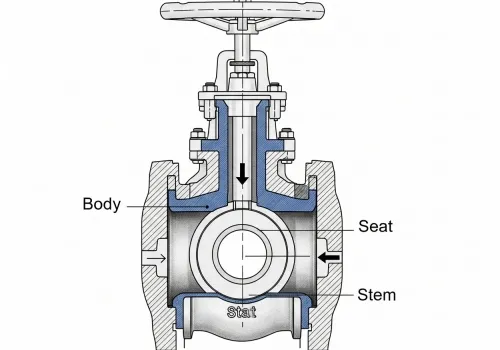

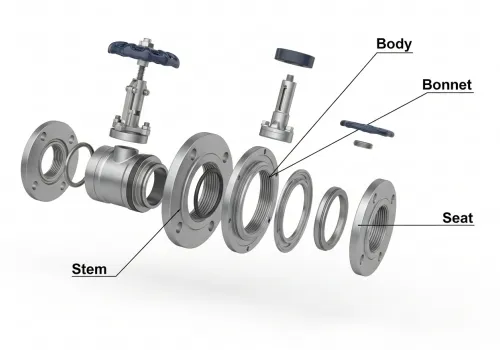

You see the hand wheel or lever on the outside of the assembly. You might not know what happens inside the metal casing. Understanding the core parts prevents bad purchasing decisions and maintenance headaches. The internal mechanism determines the valve's reliability. Every valve relies on a body, a seat, and a stem to function correctly. The body holds the pressure, the seat seals the connection, and the stem moves the closure mechanism. These parts work together to ensure the system remains leak-free under high pressure.

I have spent years looking at valve specifications. The confusion usually comes from the "Trim." Let's break down the anatomy of a valve to understand the physics behind it. The valve is not just one piece of metal. It is a collection of parts working in unison. The Body is the outer shell. It houses the internal parts and connects to the piping system. It must be strong enough to withstand the fluid pressure. The Bonnet is the cover for the opening in the body. It protects the internal parts. You remove this part when you need to repair the valve internals. The Trim refers to the internal parts that come into contact with the fluid. This includes the stem, the seat, and the disc (or gate/ball). The stem connects the actuator or handwheel to the disc inside. The seat is the surface the disc pushes against to create a tight seal. Here is a simple breakdown of the functions:

| Component | Function | Why it matters |

|---|---|---|

| Actuator | Operates the stem | It is the "muscle" that opens or closes the valve. |

| Stem | Transmits motion | If this breaks, the valve is stuck in position. |

| Disc/Gate | The barrier | This part physically stops the flow. |

| Seat | The seal | A damaged seat causes internal leaking. |

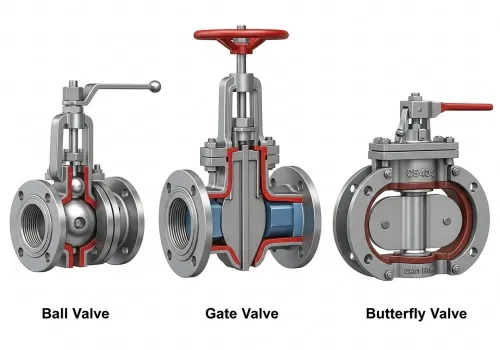

Choosing the wrong valve leads to rapid wear and system failure. Replacing them causes expensive downtime for your client. You must match the specific design to the application requirements. Different designs handle flow dynamics differently. Gate valves work best for on/off control, while globe valves excel at throttling. Selecting the right type depends on whether you need precise flow regulation or simple isolation.

I often see engineers specify the wrong valve for the job. They use a gate valve to throttle flow. This destroys the valve quickly. The high-velocity fluid erodes the bottom of the gate. This leads to leaks. You need to know the specific category of the valve. Rotary Motion Valves These valves use a spinning motion to open.

· Ball Valves: A hollow sphere sits inside the pipe. A 90-degree turn aligns the hole with the pipe. Flow is smooth. They seal very tightly.

· Butterfly Valves: A disc sits in the center of the pipe. It rotates sideways to let fluid pass. These are lightweight and good for large diameters. Linear Motion Valves These valves use a sliding motion.

· Gate Valves: A metal gate slides down to chop the flow. They should only be fully open or fully closed. They offer no resistance when open.

· Globe Valves: A plug moves up and down against the flow. This is perfect for regulating flow volume. The design forces the fluid to change direction, which drops pressure. Here is how I categorize them for purchasing:

| Valve Type | Best Use | Motion Type | Pressure Drop |

|---|---|---|---|

| Gate | Isolation (On/Off) | Linear | Low |

| Globe | Throttling (Regulation) | Linear | High |

| Ball | Quick Isolation | Rotary | Low |

| Butterfly | Large Pipes / Low Pressure | Rotary | Low |

| Check | Prevent Backflow | Automatic | Medium |

How do valves work in a check valve scenario? It is different. They do not have a handle. The flow of the fluid pushes the valve open. If the flow stops or reverses, gravity or a spring slams the valve shut. This protects pumps from damage.

Corrosive fluids destroy weak metals in a matter of weeks. A cheap valve becomes the most expensive part of your project if it fails early. Material selection determines the lifespan of the entire loop. Industrial valves face extreme temperatures and corrosive chemicals. Stainless steel, cast iron, and brass offer different levels of resistance. The right material choice ensures the internal seal remains tight and the body survives the harsh environment.

The fluid dictates the metal. I always ask my clients what is flowing inside the pipe. Is it seawater? Is it acid? Is it high-temperature steam? Cast Iron This is cheap and strong. We use it for water and sewage lines. It creates a thick body. It is brittle. It can crack if hit hard. It rusts easily if not painted. Carbon Steel This is the standard for oil and gas. It handles high pressure and high temperature well. It is tough. It withstands the rough environment of a refinery. Stainless Steel This is for corrosive environments or clean industries like food and medicine. It resists rust. It costs more. It lasts much longer. Brass/Bronze We use this for smaller pipes and low pressure. It resists corrosion well. It is soft compared to steel. The seal material is also vital. This is usually "Soft Seated" or "Metal Seated."

· Soft Seated: Uses Teflon (PTFE) or Rubber. It seals perfectly tight (bubble-tight). It cannot handle extreme heat.

· Metal Seated: Metal touches metal. It leaks a tiny amount. It survives extreme fire and heat. When you ask how do valves work over 20 years, the answer lies in the material. A carbon steel valve in a saltwater line will fail. A stainless steel valve in the same line will work for decades. You pay more upfront to save money later.

Valves are the critical control points that make piping systems safe and functional. You must understand the mechanics, the types, and the materials to make the right choice. Centerway Steel has spent decades mastering pipelines. We now bring that same expertise to our new division, Eflow Valve. We are your one-stop supplier for high-quality industrial valves that fit your exact project needs.