Hydraulic system failures can cost your company thousands of dollars in downtime and replacement parts. Often, we blame the expensive pumps for these breakdowns, but the real culprit is usually a small, overlooked component that costs a fraction of the price. A hydraulic check valve is a directional control device that allows fluid to flow freely in one direction while strictly blocking it in the opposite direction. By preventing reverse flow, it protects pumps from pressure spikes, maintains system pressure, and ensures safe operation, making it essential for any reliable hydraulic circuit.

Many engineers and purchasing managers underestimate the complexity involved in selecting this simple device. However, ignoring the specific functions of these valves can lead to catastrophic damage to your entire infrastructure. Let me explain why this component is vital for your operations and how we approach it at Eflow Valve.

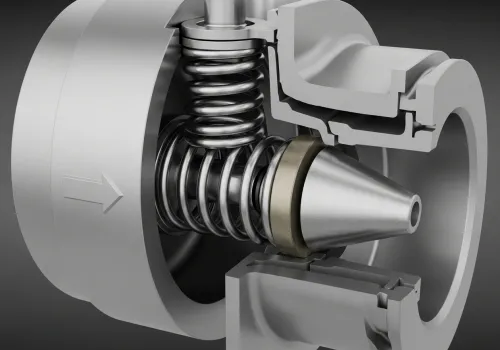

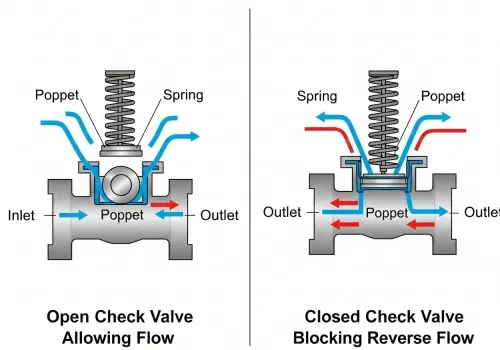

You might think all valves are created equal, but the internal mechanics determine their reliability. A simple failure here can reverse the flow and damage your upstream equipment instantly. The valve operates on a pressure differential mechanism. When the fluid pressure at the inlet exceeds the "cracking pressure" of the internal spring, the valve opens to allow flow. Conversely, if the flow tries to reverse, the spring force and back-pressure slam the poppet shut, sealing the line instantly.

At Eflow Valve, we often explain to our clients that the hydraulic check valve is self-automated. It does not require an operator or an electrical signal to work, which makes it a failsafe in many designs. In the standard design, oil flows in from one port, pushes against a poppet or ball, and exits the other side. A critical specification I always check with my purchasing clients is the "cracking pressure"—the specific amount of force required to compress the spring and open the valve. If the pressure equalizes or becomes higher on the outlet side, the valve closes immediately. This seems simple, but the application varies significantly. For example, a valve used for a heat exchanger bypass needs a stronger spring (often 65-100 psi) compared to a pump isolation valve (1-5 psi). If you install the wrong one, the system will not function correctly. I have seen systems overheat simply because a maintenance team installed a standard check valve instead of one rated for bypass duties. To help you understand the selection process, here is a breakdown of common internal designs we supply:

Valve Type

Mechanism Description

Best Application

Ball Check

Uses a spherical ball to seal against the seat.

Simple, low-cost applications; however, the ball can wear the seat over time causing leaks.

Poppet Check

Uses a guided poppet and spring.

High-pressure systems; offers a much tighter, leak-free seal compared to ball types.

Pilot-Operated

Allows reverse flow only when a pilot signal is sent.

Holding loads in place safely (e.g., crane cylinders or hydraulic presses).

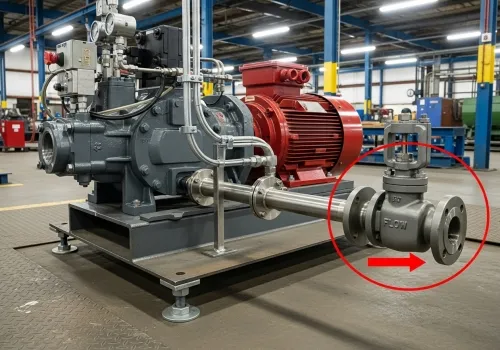

Replacing a main hydraulic pump is a nightmare for any project manager. It involves high costs, significant production delays, and labor hours. Surprisingly, the best protection against this disaster lies in a low-cost valve. A properly installed check valve located immediately downstream of the pump blocks high-pressure spikes from traveling backward. This isolation protects the pump housing and delicate seals from the shock waves created when cylinders stop moving or directionals change.

One of the most valuable lessons I learned in this industry came from a client running a plywood manufacturing plant. They were burning through hydraulic pumps every few weeks. The pump housings were actually cracking, which indicated massive pressure spikes were hitting the units. When we investigated the circuit, we found that the hydraulic check valve downstream of the pump was empty—the internal piston and spring were missing! Here is what was happening: when a large hydraulic cylinder reaches the end of its stroke, the oil is "deadheaded" rapidly. This stops the fluid moving at 15-30 feet per second instantly. The kinetic energy converts into a pressure spike that can be three times the system's normal rating. Without a functional check valve to block this wave, the shock hits the pump directly. That client’s $150 valve failure cost them $15,000 in pumps and over $50,000 in downtime. This is why I insist that my EPC clients verify the specifications of these valves. It is not just a connector; it is a shield for your capital equipment.

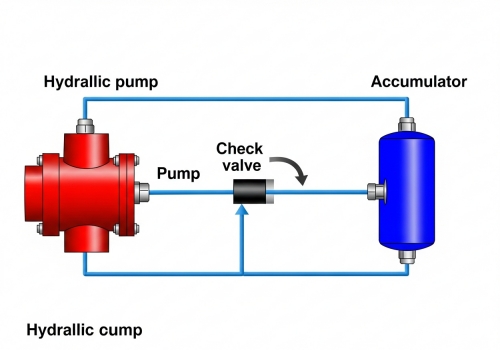

When you turn off your machinery, you assume it is safe and stable. However, gravity and trapped pressure can create dangerous situations if the fluid is not managed correctly. Check valves prevent oil from draining out of the lines back into the reservoir, which stops air from entering the system. Furthermore, they isolate hydraulic accumulators, ensuring that stored energy does not force the pump to spin in reverse.

In many construction and industrial layouts, the pump is physically located below the level of the system valves, cylinders, and motors. When the electric motor stops, gravity wants to pull the oil back into the reservoir. If the hydraulic check valve fails or leaks, the lines drain empty. This creates a vacuum that pulls air in through O-rings and seals. When you restart the system, that air causes cavitation. This sounds like gravel rattling in your pipes and it destroys metal surfaces rapidly, leading to expensive repairs. Additionally, we must consider systems with accumulators. These devices store pressurized fluid to help smooth out pulsations. If the system shuts down, that stored energy will try to escape via the path of least resistance. Without a check valve, the fluid flows backward through the pump, turning it into a motor. This reverse rotation can destroy the pump shaft and seals in seconds. I once helped a paper mill where a backup pump kept blowing seals. We found the check valve in the drain line was stuck closed, but in other cases, a stuck-open valve allows this dangerous reverse rotation. Ensuring you have a reliable supplier like Eflow Valve means you get valves that are tested to hold this seal tight, ensuring safety for your personnel and equipment.

The humble check valve is the guardian of your hydraulic system, preventing reverse flow, blocking pressure spikes, and maintaining prime. Investing in high-quality valves prevents massive financial losses and ensures operational safety.