High-pressure pipeline failures create massive safety risks and financial losses for your project. You need a valve solution that guarantees a tight seal without requiring excessive operating force. A trunnion ball valve is a quarter-turn valve where the ball is anchored at the top and bottom by a shaft, rather than floating. This design absorbs line pressure, reduces operating torque, and provides a reliable seal for high-pressure and large-diameter applications in oil, gas, and construction industries.

Many purchasing managers struggle to choose between floating and trunnion designs. They look at the initial price tag. But they often miss the long-term operational costs. I want to show you exactly how this valve works. I will explain why it saves money on actuators. I will also explain how it keeps your systems safe.

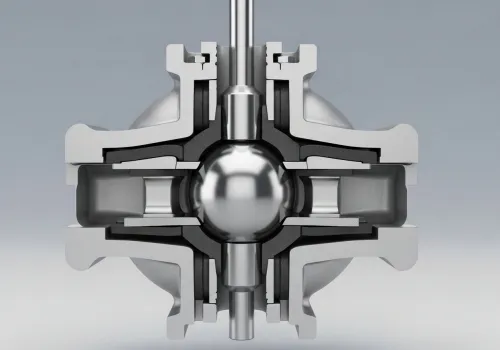

You might face leaks or high wear in your current pipeline valves. This often happens because the wrong valve type was selected for the pipe size or pressure class. In a trunnion ball valve, the ball connects to the stem on the top and a trunnion shaft on the bottom. This holds the ball firmly in place. It does not move with the flow pressure.

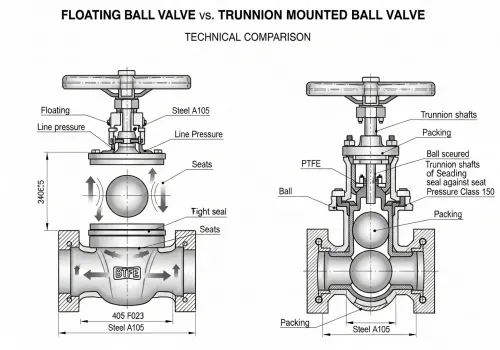

I have worked with many engineers who confuse these two types. Let me break it down. In a floating ball valve, the pressure pushes the ball downstream against the seat. This creates the seal. But in high-pressure lines, this pressure is too high. It damages the seat. It makes the valve hard to turn. The trunnion design is different. The ball stays fixed. The pressure does not push the ball. Instead, the pressure pushes the seats against the ball. This is a critical difference. It means the ball rotates freely. It does not grind against the downstream seat. I see this design as a necessity for large pipes. Usually, for sizes above 4 inches or high-pressure classes like Class 600, we recommend trunnion mounted valves. The fixed ball design handles the heavy load. The floating design cannot handle it. Here is a simple comparison to help you decide:

| Feature | Floating Ball Valve | Trunnion Ball Valve |

|---|---|---|

| Ball Movement | Moves/Floats downstream | Fixed/Anchored in place |

| Sealing Mechanism | Pressure pushes ball into seat | Spring-loaded seats push into ball |

| Torque Requirement | High (friction increases with pressure) | Low (friction is minimized) |

| Best Application | Small sizes, low to medium pressure | Large sizes, high pressure |

| Wear and Tear | Higher on downstream seat | Even distribution, longer life |

High operational costs often come from oversizing your actuators. You might be spending too much money on power and equipment just to open and close a valve. A trunnion ball valve significantly lowers torque requirements because the line pressure is absorbed by the trunnion bearings, not the sealing surfaces.

Let's look at the physics here. When you have a floating valve under 100 bar of pressure, that pressure pushes the ball hard against the seat. You need a huge amount of force to turn that handle. You need a massive actuator. That costs a lot of money. It also takes up space. With the trunnion design, I see a huge advantage for my EPC clients. The bearings absorb the load. The friction is very low. You can use a smaller, cheaper actuator. Over the course of a large project, this saves thousands of dollars. Also, we need to talk about sealing at different pressures.

· Low Pressure: What happens when there is no pressure? In a floating valve, you might get a leak. But in a trunnion valve, the springs behind the seat push against the ball. This means you get a perfect seal at 0 bar and at 200 bar. I always tell my clients that versatility is key. You do not want a valve that only works at peak capacity. You need a valve that works during startup and shutdown too. At Eflow Valve, we use specialized spring designs. We test them to ensure they maintain contact with the ball even after thousands of cycles. This extends the maintenance interval. It keeps your plant running longer without downtime.

Safety regulations in the oil and gas industry are getting stricter. You need a way to isolate pipeline sections completely and release trapped pressure without venting the whole line. The trunnion ball valve creates a Double Block and Bleed (DBB) system. This means it seals from both upstream and downstream sides, while allowing the body cavity to vent. This is my favorite feature for safety. Imagine a pipeline full of gas. You close the valve. In a standard valve, gas might still be trapped inside the valve body. If the temperature rises, that gas expands. It can explode. This is a serious danger. The trunnion design solves this. It has two independent seats.

1. Block 1: The upstream seat seals the fluid.

2. Block 2: The downstream seat seals the fluid.

3. Bleed: The center cavity has a drain or bleed valve. When the valve is closed, fluid is trapped in the ball cavity. If pressure builds up inside this cavity (due to heat from the sun or process fluid), the spring-loaded seats allow the pressure to "burp" or relieve itself back into the line. Or, you can manually open the bleed valve to check if the seal is holding. I often advise clients on API 6D standards. This standard requires this pressure relief. It usually happens at 1.1 to 1.33 times the pressure rating. For maintenance teams, this is a lifesaver. They can close the valve. They can open the bleed. If nothing comes out, they know 100% that the line is safe to work on. They do not have to guess. At Eflow Valve, we subject every DBB valve to rigorous pressure testing. We make sure both seats hold pressure independently. We ensure the bleed function works exactly as calculated. This gives you peace of mind when you install our products in critical infrastructure.

The trunnion ball valve is the superior choice for high-pressure, large-diameter pipelines due to its anchored design, low torque operation, and Double Block and Bleed safety features.