Selecting the right butterfly valve is crucial for ensuring efficient flow control, minimizing maintenance, and maximizing system performance. With various types, materials, and designs available, making the right butterfly valve choice depends on factors like pressure, temperature, fluid type, and installation requirements.

This guide will help you choose the right butterfly valves by covering key selection criteria, common types, and industry best practices.

A butterfly valve is a quarter-turn valve that regulates flow using a rotating disc. It is lightweight, cost-effective, and suitable for large-diameter pipelines.

· Body (cast iron, stainless steel, PVC, etc.)

· Disc (rotates to open/close flow)

· Stem (connects disc to actuator)

· Seat (ensures tight sealing)

· Actuator (manual lever, gear, pneumatic, or electric)

· Cast Iron – Budget-friendly, good for water & air.

· Stainless Steel (SS304/SS316) – Corrosion-resistant, ideal for chemicals & seawater.

· PVC/CPVC – Lightweight, used in corrosive & low-temperature fluids.

· Ductile Iron – Stronger than cast iron, handles higher pressures.

· EPDM (Ethylene Propylene Diene Monomer) – Water, acids, mild chemicals.

· Viton (FKM) – High-temperature oils, fuels, solvents.

· PTFE (Teflon) – Aggressive chemicals, extreme temperatures.

· Metal Seat – High-pressure steam, abrasive media.

· Low Pressure (PN10/PN16) – HVAC, water systems.

· Medium Pressure (PN25/PN40) – Industrial processes.

· High Pressure (PN64 & above) – Oil & gas, power plants.

· Manual (Lever/Gear) – Small valves, easy operation.

· Pneumatic – Fast response, automated systems.

· Electric – Precise control, remote operation.

· Hydraulic – High-torque applications.

❌ Ignoring Fluid Compatibility – A rubber seat may degrade in oil applications.

❌ Overlooking Pressure Ratings – Using a low-PN valve in high-pressure systems can cause failure.

❌ Wrong Actuator Selection – Manual valves may be inefficient for large pipes.

❌ Poor Installation – Misaligned flanges lead to leaks.

To choose the right butterfly valves, consider:

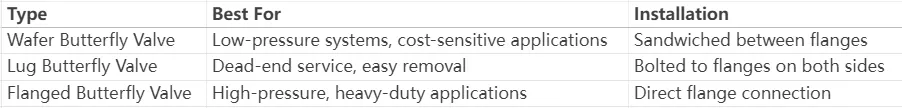

✔ Valve type (wafer, lug, flanged)

✔ Material compatibility (body, disc, seat)

✔ Pressure & temperature requirements

✔ Actuation method (manual or automated)

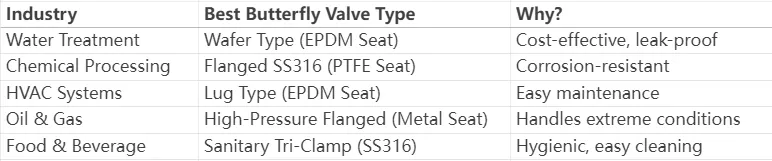

✔ Industry-specific needs

By following these guidelines, you can ensure optimal performance, longevity, and cost-efficiency in your piping systems.