Do you struggle with regulating flow pressure in your pipeline projects? Choosing the wrong valve often leads to leaks, system failures, and expensive maintenance down the road. A globe valve works by using a linear motion stem to move a rounded plug (or disc) into or out of a seating surface. This movement widens or narrows the gap for fluid to pass through. It is specifically designed to throttle, start, and stop flow with high precision.

Many purchasing managers I talk to think all valves are the same, but the internal design changes everything. I want to share exactly how these valves function so you can make the right choice for your next EPC project.

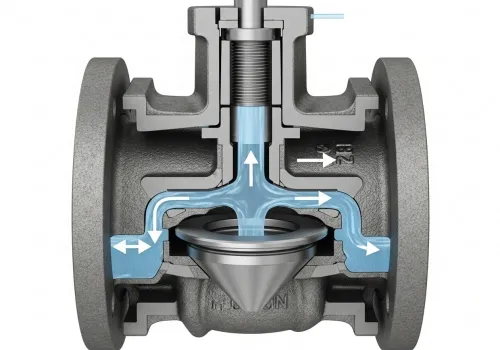

Are you curious about what actually happens inside the valve body when you turn the handle? The internal mechanism forces fluid to change direction twice, creating an S-shaped or Z-shaped path. The threaded stem moves the plug vertically against the flow, allowing you to finely adjust the volume of liquid passing through the orifice.

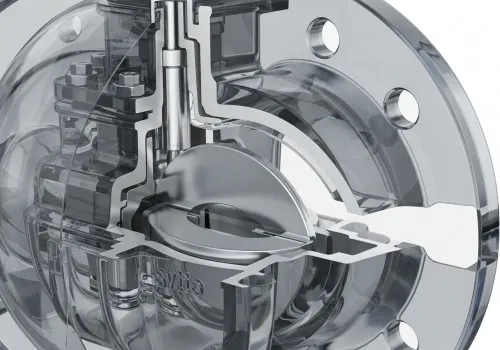

To truly understand how does a globe valve work, you have to look at the relationship between the seat and the disc. Unlike a ball valve that rotates, a globe valve operates like a cork in a bottle. When I first started at Eflow Valve, I was fascinated by this simple yet powerful design. The fluid enters the valve body and must turn 90 degrees to go up through the seat ring. Then, it turns another 90 degrees to exit the valve. This is often called a tortuous flow path. Because the fluid hits the bottom of the plug (or disc), the flow is controlled by the distance between the plug and the seat. I remember a client from a refinery project who was confused about why his system pressure dropped so much. I explained that this specific "Z" shape causes a significant pressure drop because of the resistance. However, this resistance is exactly what makes the globe valve so good at throttling. You can set the plug at 10%, 50%, or 90% open, and it will hold that flow rate steadily. The stem is usually threaded, meaning it takes several turns of the handwheel to close the valve completely. This prevents water hammer, which is a sudden pressure wave that can damage pipes.

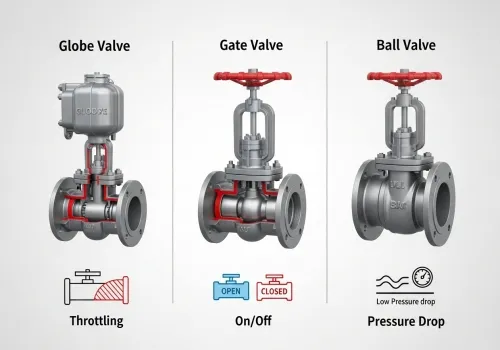

Do you know which valve type offers the best balance between sealing capability and flow regulation? You should choose a globe valve when you need to regulate flow rather than just turning it on or off. While gate valves are for full flow and ball valves are for quick shut-off, globe valves offer superior throttling abilities and durable sealing.

In my 18 years of experience working with construction and industrial pipelines, I have seen many engineers make the mistake of using gate valves for throttling. This ruins the valve quickly. Here is a breakdown to help you compare them. At Eflow Valve, we often use this table to help clients decide:

| Feature | Globe Valve | Gate Valve | Ball Valve |

|---|---|---|---|

| Primary Function | Throttling (Regulating) | Isolation (On/Off) | Isolation (On/Off) |

| Flow Resistance | High (Significant pressure drop) | Very Low | Low |

| Shut-off Speed | Slow (Multi-turn) | Slow (Multi-turn) | Fast (Quarter-turn) |

| Leakage Risk | Low (Excellent seal) | Moderate (Seat wear) | Low (Good seal) |

| Maintenance | Easy (Trim is accessible) | Difficult (Often needs removal) | Moderate |

So, how does a globe valve work to reduce wear? In a globe valve, the contact between the seat and the disc only happens right at the moment of closing. In a gate valve, the gate slides against the seat the entire time it opens or closes, which causes scratches. This is why globe valves last longer in frequent-use situations.

I once worked with a power plant manager who replaced his control valves every six months. We switched him to our high-quality stainless steel globe valves. Because the seating surface was not rubbing against the disk constantly, his maintenance cycle extended to two years. This saved his company a fortune in downtime.

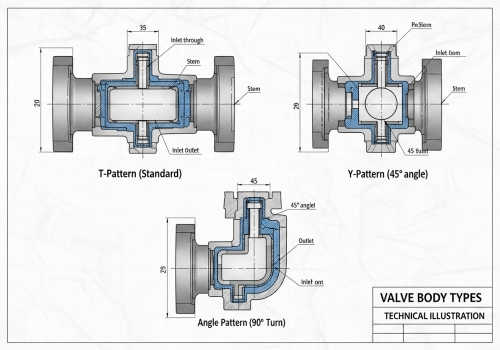

Are you aware that the shape of the valve body can solve different piping problems? The best type depends on your pressure requirements and piping layout. The standard Tee-pattern is best for severe throttling, while the Y-pattern reduces pressure drop, and the Angle pattern eliminates the need for an extra pipe elbow.

When you ask how does a globe valve work in different configurations, the answer lies in the body shape. The standard globe valve, or T-pattern, has the highest pressure drop. The diaphragm moves vertically. This is standard for most water and oil lines where some pressure loss is acceptable. However, if you are dealing with high-pressure steam, the pressure drop might be too much. This is where the Y-Type Globe Valve comes in. The stem and seat are angled at 45 degrees. This makes the flow path much straighter. It keeps the throttling ability but reduces the resistance. At Eflow Valve, we supply many of these to thermal power generation projects where efficiency is key. Then there is the Angle Globe Valve. Imagine you have a pipe that needs to turn a corner anyway. Instead of buying a valve and an elbow fitting, you can use an Angle valve. It acts as both. The flow enters the bottom and exits the side. This saves installation time and reduces the number of joints that could leak. Material selection is also vital. For our clients in the Middle East and Southeast Asia, we often provide Carbon Steel for oil lines. But for food processing or chemical plants, we use Stainless Steel to stop corrosion. We even have "Bellows Seal" globe valves for dangerous gases where zero leakage is allowed. The stem is sealed inside a metal accordion structure so nothing can escape into the air.

A globe valve works by using a plug to throttle fluid flow against a seat, offering precise control that other valves cannot match. If you need reliable valves for your next project, Eflow Valve is here to help. We combine global standards with high-quality production to support your pipeline needs.