The hissing sound of leaking air is the sound of money leaving your factory. You ignore it, but this small component failure might be destroying your expensive machinery right now. An air check valve for air compressor acts as a security gate, allowing air to flow in only one direction. It prevents high-pressure air from rushing back into the pump when the machine stops. This simple device protects the compressor from damage and ensures energy efficiency in your piping system.

Many people overlook this small valve. They focus on the motor or the tank. But in my experience at Eflow Valve, I have seen entire projects delayed because of cheap, faulty valves. I want to explain exactly how this works so you do not make the same mistake.

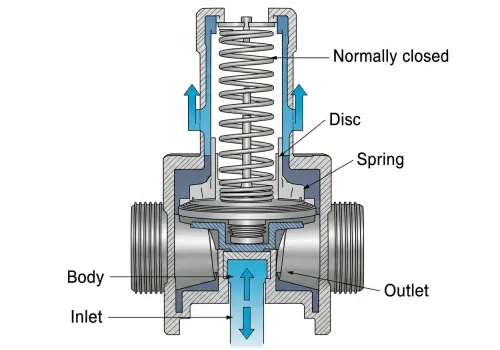

You might think the internal design is complex. Actually, the genius of this part lies in its absolute simplicity and reliability. The valve usually contains a disc or a ball held in place by a spring. When air flows forward, it pushes the spring open. When airflow stops, the spring and back-pressure slam the valve shut immediately.

I have spent years in this industry, and I appreciate simple engineering. The air check valve for air compressor is a perfect example of efficient design. It relies entirely on a pressure difference to operate. When the compressor is running, it pushes air out with great force. This pressure is higher than the force of the spring inside the valve. Consequently, the disc moves away from the seal, and air passes through freely to the tank. However, the moment the compressor stops, the physics change completely. The pressure from the compressor side drops to zero. But the pressure in your air tank remains very high. This high pressure tries to rush back into the pump. Now, the tank pressure works with the spring. They push the disc or ball hard into its seat. The seal becomes tighter as the pressure gets higher. This is a "fail-safe" design. At Eflow Valve, we ensure our valves can handle this cycle thousands of times. If the seat is soft, it wears out quickly. If the spring is too weak, the valve flutters and makes noise. We often have to advise clients on the right material choice based on their operating environment. Here is a breakdown of the materials we often use to ensure this mechanism lasts:

| Material | Pros | Cons | Best Application |

|---|---|---|---|

| Brass | Corrosion resistant, durable | Higher cost than plastic | General industrial compressors |

| Stainless Steel | High heat and chemical resistance | Expensive | Harsh chemical environments |

| Cast Iron | Very strong, handles high heat | Can rust over time | Large industrial piston pumps |

| Plastic/PVC | Cheap, lightweight | Brittle, low heat tolerance | Small DIY home compressors |

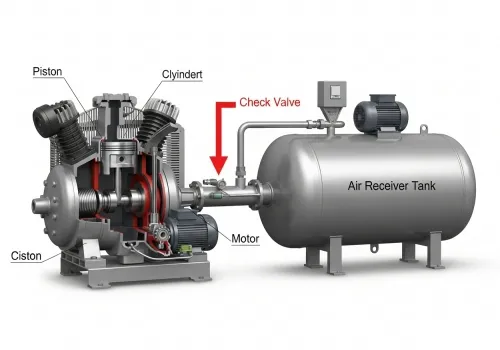

Finding these valves can be a puzzle. Different machines hide them in different places depending on how they generate pressure. On piston compressors, you find them between the pump head and the tank. On rotary screw compressors, they sit at the inlet valve and the outlet element to stop oil from spraying backward.

Let us look closer at the specific locations because this knowledge is vital for maintenance. If you are sourcing parts for an EPC project, you need to know exactly what you are buying and where it goes. Reciprocating Piston Compressors: These are the most common units in construction. You have valves inside the piston head to control intake and exhaust, but the main external air check valve for air compressor is on the discharge pipe. This is the pipe connecting the pump to the tank. Why is it there? When the motor stops, the unloader valve empties the pressure in that small pipe. This makes the next start-up easy for the motor. The check valve stops the huge volume of air in the tank from escaping during this "blow-down" process. Without it, the tank would empty every time the motor turned off. Rotary Screw Compressors: These are more complex and are used for continuous industrial air. I remember a client who had oil spraying out of his intake filter. It was a mess on the shop floor. The cause was a failed inlet check valve. On screw units, the valve prevents the air-oil mixture from "vomiting" back out when the system shuts down. There is also a minimum pressure valve at the outlet. It ensures the system maintains enough internal pressure to lubricate itself before sending air to the plant. Here is why location matters for your maintenance team:

· Tank Inlet: Easy to access, most common failure point.

· Screw Element: Critical for preventing oil contamination.

You might blame the wrong part when things go wrong. A bad check valve often tricks people into replacing the pressure switch instead. If you hear air leaking from the pressure switch when the compressor is off, the switch is fine. The check valve on the tank is leaking air back into the unloader line.

This is the most common diagnostic error I see in the field. Let me walk you through the logic so you can save time. The pressure switch has a small "unloader" valve attached to it. Its job is to release the air trapped in the piston head when the machine stops. It should go "Pssssht" for about two seconds and then stop. This is normal. However, if it keeps hissing continuously after the machine has stopped, the air is coming from somewhere else. Since the pump is off, the air must be coming from your main tank. It travels backward through the failed air check valve for air compressor, goes up the discharge line, and exits out the unloader valve. If you replace the switch, the leak continues because the switch was never the problem. You must replace the check valve. Another sign is hard starting. If the valve sticks open, the motor has to push against full tank pressure immediately upon starting. This can trip breakers, dim lights, or burn out capacitors. At Eflow Valve, we test for these scenarios rigorously. We want to ensure our clients in the oil and gas or construction industries do not face unexpected downtime. Here is a simple troubleshooting guide I use:

| Symptom | Probable Cause | Solution |

|---|---|---|

| Continuous leak at pressure switch (machine off) | Leaking Tank Check Valve | Clean or replace the check valve |

| Motor hums but won't turn | Back-pressure on pump head | Check unloader and check valve |

| Oil in air filter (Screw type) | Inlet Check Valve failure | Replace inlet valve kit immediately |

| Tank loses pressure overnight | Leaking Check Valve or fittings | Use soapy water to find the leak |

The air check valve for air compressor is small but vital. It controls airflow direction, protects your motor, and ensures safety. Always choose high-quality valves to avoid costly system failures.