You worry about pipeline leaks and costly downtime. Choosing the wrong valve causes these headaches. I will show you how to pick the perfect valve to stop these problems. To select the correct industrial ball valve, you must analyze the service fluid, operating pressure, and temperature. You also need to determine the actuation method and verify material compatibility. Answering these questions ensures your system runs safely and efficiently.

I see many engineers struggle with this process. It looks simple. But it is actually complex. I want to guide you through it. I will break down the key questions you must ask.

Ignoring fluid properties leads to corrosion. This destroys your valves quickly. You must understand exactly what flows through your pipes to prevent failure. The nature of the media dictates the valve design. You must check if the fluid is corrosive, abrasive, or flammable. You must also match the valve rating to the pipeline's maximum pressure and temperature.

I always tell my clients at Eflow Valve to look at the fluid first. You must ask if it is gas, liquid, or a semi-solid slurry. This is the most important step. A slurry contains solid particles. These particles act like sandpaper. They scratch soft valve seats. You need hard metal seats for slurries. A standard industrial ball valve will fail here. You must also think about the chemical nature. Acids require stainless steel or special alloys. Water is fine with simpler materials. Temperature is the next big factor. High heat makes metal expand. It makes plastic seals melt. If the temperature changes fast, we call this thermal shock. This can crack the valve body. You must tell your supplier the minimum and maximum temperatures. Pressure is just as critical. Every valve has a pressure rating. You cannot exceed this limit. The valve will leak or burst. You must check the pressure class of your flanges too. They must match the valve. You also need to look at the outside environment. Is the valve inside a factory? Or is it on an oil rig in the ocean? Salty air causes rust from the outside. You need special paint or coatings for this. You must consider every angle of the environment. This ensures the valve lasts a long time.

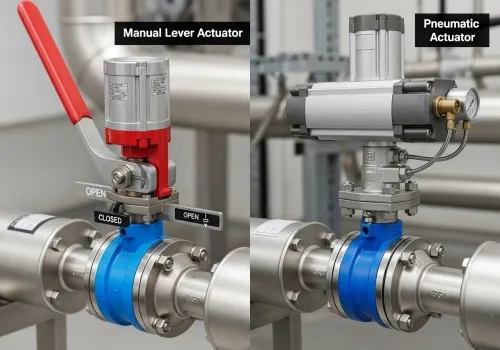

Manual operation is slow for emergencies. This risks safety in critical moments. You need to choose the right control method to match your system needs. You must decide between manual, pneumatic, or electric actuation based on cycle frequency. High-cycle applications need durable pneumatic actuators, while infrequent isolation valves work well with simple manual levers.

You need to think about how often you open the valve. We call this the duty cycle. Some valves stay open for months. You only close them for maintenance. A manual lever is cheap and fine for this. But sometimes you need to open and close a valve every minute. A human cannot do this. You need an automated industrial ball valve for this job. You have three main choices for automation. Pneumatic actuators use air. They are very fast. They are also safe. We use them in explosion-proof areas. Electric actuators use a motor. They are very precise. They are good if you do not have an air supply. Hydraulic actuators use fluid pressure. They are for very big, heavy valves. You must also calculate the torque. This is the turning force. A big valve needs a lot of force. The actuator must be strong enough. If it is too weak, the valve sticks. You also need to decide the failure mode. If the power goes out, what happens? Does the valve close? Does it open? Or does it stay put? We call this fail-safe. Spring-return actuators close the valve automatically without power. This prevents disasters. You must plan for the worst-case scenario.

Cheap materials fail under pressure. This causes dangerous leaks and accidents. You must insist on certified, high-quality materials to protect your investment and your people. The valve body and seat materials must resist chemical attack and wear. You should also verify certifications like API, CE, or ISO to ensure the manufacturer meets strict quality and safety standards.

Material selection is critical. I see many buyers choose the cheapest option. This is a mistake. The chemical in your pipe will eat the wrong metal. Stainless steel resists rust. Carbon steel is strong but rusts. For the seats, you have choices too. PTFE is common. But it melts in high heat. Metal seats are better for extreme heat. We at Eflow Valve test everything. You should ask for certificates. Look for API 6D for oil and gas. Look for CE marks for Europe. These papers prove quality. A cheap valve has no papers. A good industrial ball valve has a paper trail. You must also ask about testing. Does the factory pressure test every valve? Or do they just test one in a batch? You want 100% testing. Here is a simple guide I use for materials:

| Material | Best Application | Cost | Durability |

|---|---|---|---|

| Brass | Water, Air, Low Pressure | Low | Medium |

| Stainless Steel (304/316) | Corrosive Chemicals, Food | High | High |

| Carbon Steel | Oil, Gas, High Pressure | Medium | High |

| Monel/Inconel | Seawater, Acids, Severe Service | Very High | Very High |

| PVC/Plastic | Water, Mild Chemicals | Very Low | Low |

You must also think about maintenance. Good materials last longer. They need less repair. A cheap valve breaks often. You spend more money on labor to fix it. A high-quality valve costs more today. But it saves money over five years. We call this the Total Cost of Ownership. You should always buy for the long term.

You must analyze the media, actuation method, and materials carefully. Answering these questions ensures you buy a safe, durable valve that saves you money and prevents accidents.