Choosing the right big size ball valve is a critical step in designing a safe, efficient, and durable industrial pipeline system. From oil & gas to power generation and water treatment, large-diameter valves play a vital role in controlling fluid flow under high pressure and extreme temperatures.

In this guide, we’ll explore the classification big size ball valve system in detail — how ball valves are categorized by structure, material, and connection — and how this classification helps engineers and buyers select the right model for their specific applications.

A big size ball valve generally refers to any valve with a nominal diameter (DN) of 200 mm (8 inches) or above. These valves are designed to handle large flow volumes, high pressures, and harsh industrial media such as crude oil, gas, or seawater.

Unlike small valves used for simple on/off control, large ball valves must offer:

· High sealing reliability

· Easy operation under high torque

· Long service life

· Compatibility with automation (electric or pneumatic actuators)

Understanding the classification of big size ball valves is essential for ensuring optimal performance in these demanding conditions.

Proper big size ball valve classification is not just about terminology — it directly affects safety, cost, and maintenance. The right classification ensures that:

· The valve withstands design pressure and temperature limits

· Materials are compatible with process fluids

· Actuation and installation are efficient

· Leakage and downtime risks are minimized

In other words, knowing the classification for big size ball valves helps engineers make technically sound, cost-effective decisions.

Ball valves can be categorized according to how the ball is supported and sealed inside the body.

· The ball is supported only by the valve seats.

· Suitable for low to medium pressure (usually up to Class 600).

· Offers simple design and lower cost, but not ideal for very large diameters due to higher seat wear.

· Commonly used in water treatment and general industrial applications.

· The ball is anchored by trunnions (shafts) at both ends.

· Excellent for high pressure, large diameter (DN300+) systems.

· Reduces seat load and torque, ensuring long service life.

· Widely used in oil & gas pipelines, petrochemical plants, and power stations.

· The body is completely welded, providing a leak-free structure.

· Ideal for underground or long-distance pipelines where maintenance access is limited.

· Offers excellent durability and corrosion resistance.

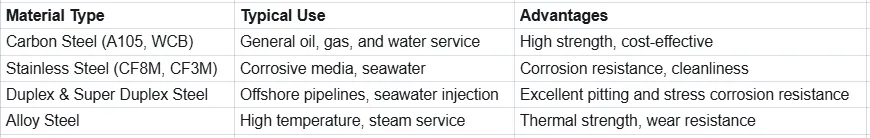

Material selection is a vital part of the classification big size ball valve system because it determines resistance to pressure, temperature, and corrosion.

When choosing materials, always consult ASME B16.34 or API 6D for pressure-temperature ratings.

Connection type defines how the valve integrates into the pipeline system:

· Flanged End (RF, RTJ):

The most common type, easy to install and replace. Used in above-ground systems.

· Welded End (BW, SW):

Offers stronger sealing and no flange leakage — ideal for buried or high-pressure pipelines.

· Threaded End:

Limited to small-size valves, rarely used in big size valves due to sealing concerns.

· Clamp or Hub Connectors:

Used for specialized applications in offshore or modular systems.

Each connection type should match the pressure class (ASME Class 150–2500) and pipeline design.

The operation mechanism is another way to categorize ball valves:

· Manual Operation:

Simple, low-cost, used for smaller diameters or emergency shut-off.

· Gear Operated:

Common for large diameters where manual torque is too high.

· Electric Actuated:

Enables remote or automated control. Suitable for industrial control systems (SCADA).

· Pneumatic or Hydraulic Actuated:

Ideal for fast or emergency shut-off, especially in oil & gas pipelines.

Automation is increasingly part of modern big size ball valve classification, enabling smarter and safer operation.

When evaluating the classification of big size ball valves, engineers should reference key international standards:

· API 6D – Specification for pipeline valves

· ASME B16.34 – Valves: Flanged, Threaded, and Welding End

· ISO 14313 – Petroleum and natural gas industries – Pipeline transportation systems

· EN 12516 – Industrial valves – Strength and pressure testing

· NACE MR0175 / ISO 15156 – Materials for sour service (H₂S environments)

Compliance with these standards ensures reliability, safety, and compatibility across global markets.

Here’s a practical method to select the correct valve based on classification big size ball valve principles:

1. Define your medium: gas, oil, water, steam, or slurry

2. Check pressure and temperature: choose appropriate pressure class and material

3. Select structure type: floating for small size / trunnion for large size

4. Choose connection type: flange or welded according to system design

5. Consider actuation method: manual, gear, or automated

6. Verify standard compliance: API 6D, ASME, or ISO as required

7. Evaluate maintenance needs: welded or split-body design

Following this method ensures that your valve selection matches both technical and operational requirements.

· Classification big size ball valve knowledge is essential for correct valve selection.

· Major categories include structure, material, connection, and operation type.

· Trunnion mounted designs dominate large-diameter, high-pressure systems.

· Material selection and standard compliance are critical for safety and reliability.

· Using a structured approach saves cost, improves performance, and prevents failures.

By understanding the complete big size ball valve classification, engineers and procurement teams can confidently choose the best valve for any application.

If you’re looking for expert advice or customized design assistance for big size ball valves, contact our engineering team. We provide API-certified valves and can recommend the ideal product based on your flow medium, pressure, and installation needs.