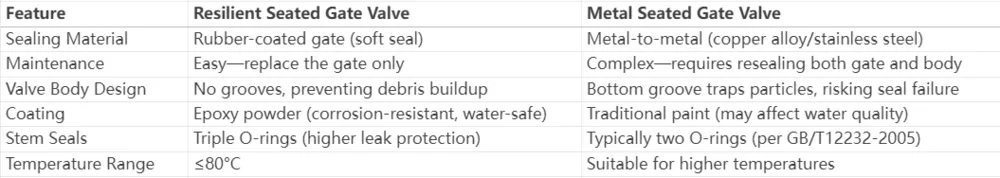

When selecting gate valves for water supply and drainage systems, understanding the differences between resilient seated gate valve vs metal seated gate valve is crucial. Both types serve distinct purposes, with varying performance characteristics in terms of sealing, durability, and maintenance.

A resilient seated gate valve is primarily used in water and wastewater systems, operating at temperatures ≤80°C, nominal pressure ≤PN25, and diameters ≤800mm. Common materials include cast iron, ductile iron, cast steel, or stainless steel. Key standards include:

· CJ/T216-2013 (Soft-sealed gate valves for water supply and drainage)

· GB/T 24924-2010 (Elastomer-sealed gate valves for water supply systems)

· AWWA C509:2001

1. Soft Sealing Mechanism

o The metal gate is fully encapsulated with EPDM or NBR rubber using vulcanization molding.

o Sealing relies on the rubber's elastic deformation, ensuring zero leakage and excellent corrosion resistance.

o The wedge-shaped gate reduces wear on the sealing surface.

2. No Cavity Design

o The valve body has no grooves, preventing debris accumulation.

o The flow path matches the pipe diameter, ensuring minimal flow resistance.

3. Epoxy Powder Coating

· Applied via electrostatic spraying and baked at 180°C–200°C for a durable, non-toxic coating.

· Advantages:

o Excellent adhesion without primer

o High hardness, scratch resistance, and impact strength

o Superior resistance to water, acids, alkalis, and saltwater

4. Triple O-Ring Stem Sealing

o Prevents external leakage and allows for online replacement under pressure.

o Includes a dust seal to block contaminants.

5. Maintenance-Friendly Design

o Hex socket screws with wax sealing prevent rust, simplifying future disassembly.

· Resilient seated valves dominate in potable water systems due to their hygienic design and zero leakage.

· Metal seated valves remain essential for high-temperature or aggressive media.

The choice between a resilient seated gate valve vs metal seated gate valve depends on operational needs. Soft-sealed valves excel in corrosion resistance, ease of maintenance, and water safety, while hard-sealed variants handle extreme conditions. For modern water systems, resilient seated gate valve vs metal seated gate valve comparisons increasingly favor rubber-sealed designs for their reliability and eco-friendly properties.

By understanding these differences, engineers can optimize valve selection for efficiency and longevity.