Three way ball valves are essential components in fluid control systems, offering superior versatility compared to standard two-way valves. With their unique design allowing for multiple flow configurations, these valves play a critical role in industries ranging from oil and gas to HVAC and water treatment. This comprehensive guide explains how a three way ball valve functions, its key design variations, and where it delivers the most value in industrial and commercial applications.

A three way ball valve controls fluid flow using a rotating sphere (the "ball") with precisely machined ports. The ball's position determines the flow path between the three valve openings, enabling:

· Flow diversion (directing liquid/gas between two paths)

· Flow mixing (combining two inputs into one output)

· Shut-off capability (blocking flow entirely)

The valve is operated manually via a handle or automatically using pneumatic/electric actuators for remote control.

1. Valve Body – Typically stainless steel, brass, or PVC for corrosion resistance

2. Rotating Ball – Contains an L-shaped or T-shaped bore for flow control

3. Valve Seats – Provide a tight seal when closed (often PTFE for durability)

4. Stem – Transmits rotational force from the handle to the ball

5. Actuator (Optional) – Allows automated control in industrial systems

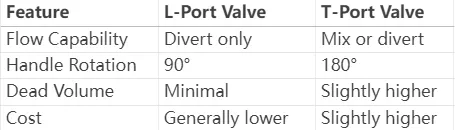

· Flow Pattern: 90° turn diverts flow between two ports while blocking the third

· Best For: Switching between two sources (e.g., alternate water supplies)

· Common Applications:

o Cooling system bypass valves

o Dual-source fuel lines

o Process switching in chemical plants

· Flow Pattern: Can mix two inflows into one or split one inflow into two

· Best For: Blending applications where continuous flow is needed

· Common Applications:

o Hot/cold water mixing in HVAC

o Chemical dosing systems

o Industrial process blending

Comparison Table:

· Pipeline flow diversion

· Pressure regulation in refineries

· Crude oil blending systems

· Safe mixing of reactive compounds

· Corrosive fluid handling (requires special alloys like Hastelloy)

· Zone control in heating/cooling networks

· Energy-efficient water mixing

· Filter backwashing systems

· Sludge flow redirection

· Hygienic design (3A compliant valves available)

· Precise ingredient blending

✔ Material Compatibility – Match wetted parts to fluid type (e.g., stainless steel for corrosive media)

✔ Pressure/Temperature Rating – Ensure valve meets system requirements

✔ Port Configuration – L-port for switching vs. T-port for mixing

✔ Actuation Method – Manual, pneumatic, or electric based on automation needs

✔ Industry Certifications – API 6D, ISO 9001, or FDA compliance where required

Pro Tip: For high-cycle applications, specify reinforced PTFE seats for longer service life.

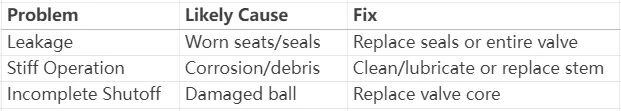

· Lubricate stems annually (check manufacturer guidelines)

· Inspect seals for wear in abrasive media applications

· Cycle valves periodically if used infrequently

· Smart Valves: IoT-enabled versions with flow monitoring

· Advanced Materials: Ceramic coatings for extreme wear resistance

· Compact Designs: Space-saving valves for modular systems

From simple flow diversion to complex mixing applications, the three way ball valve remains one of the most flexible flow control solutions available. By understanding the differences between L-port and T-port configurations, along with proper selection criteria, engineers can optimize these valves for virtually any industrial process.

For your next critical piping project, request a quote on our certified three way ball valves today. Let our engineering team help you select the perfect valve solution